TEST SIEVES FOR CONSTRUCTION MATERIALS

Shop Forney’s wide range of sieves for all aspects of construction material sample preparation, mix design, QC and general particle analysis. Forney offers test sieves of 3, 6, 8, 10, 12 and 18 inches, as well as mesh sizes ranging from 4 inches to 20 µ in brass and stainless steel.

Sieve Kits

Sieving Accessories

Sieves by Height

Sieves by Dimension

Sieves by Type

About Sieves

+ What are sieves?

Sieves are devices with meshed bottoms used to separate particles of different sizes. They are used to classify and separate construction materials like soil, aggregates, or asphalt into different particle sizes for testing and analysis.

+ What are the different types of sieves?

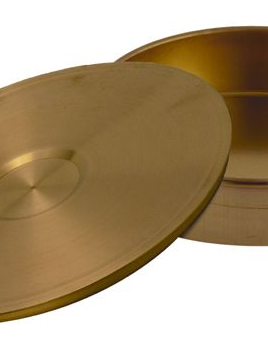

Sieves can be made of various materials, including stainless steel and brass.

Stainless steel sieves are commonly used for general-purpose sieving applications across various construction materials, including soil, aggregates, and asphalt. They offer durability and corrosion resistance, making them suitable for most testing environments.

Brass sieves are often preferred for applications requiring higher precision and accuracy, such as in particle size analysis, where extremely fine particles need to be separated. They are also used in specialized testing where the material being sieved may react with stainless steel, affecting the results. Additionally, brass sieves are sometimes specified in certain standards or regulations for specific tests.

+ What is soil particle size analysis?

Soil particle size analysis is a process of determining the distribution of particle sizes within a soil sample to understand its properties.

+ What is the Marshall Test for Asphalt and why are sieves necessary for it?

The Marshall Test is a method to measure the stability and flow properties of asphalt mixtures. Sieves are necessary to separate aggregates into different sizes before mixing them with asphalt binder for testing.

+ What sieving accessories are required for sieve testing?

- Sieve cleaners: Tools used to remove particles lodged in the mesh of sieves.

- Sieve pans and covers: Containers used to hold materials during sieving and prevent spillage.

- Magnifying comparator: A device used to inspect and measure particle sizes retained on sieves.

- Sieve brushes: Brushes that are used to clean sieves and remove particles stuck on the mesh.

+ Why do sieves come in different sizes and dimensions?

Different types of materials require different sieve sizes and dimensions. Mesh openings (the aperture size) are informed by ASTM and ISO sieve specifications and tolerances for the intended application. 8 inch and 12 inch sieve frames are the most commonly used size.

+ What is backing cloth?

Sieve backing cloth reinforces the mesh of the sieve to extend the sieves life, helping to prevent sagging, tearing, and mesh openings from distorting after repeated use.

Important Sieving Specifications and Standards

- ASTM E11: Standard Specification for Wire Cloth and Sieves for Testing Purposes

- ISO 3310-1: Test Sieves—Technical Requirements and Testing

- ASTM C136: Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates

- ISO 565: Test sieves—Metal wire cloth, perforated metal plate and electroformed sheet

- ASTM D6913: Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis

- ASTM D75: Standard Practice for Sampling Aggregates

- ISO 565: Test sieves—Metal wire cloth, perforated metal plate and electroformed sheet

- ASTM D4791: Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate