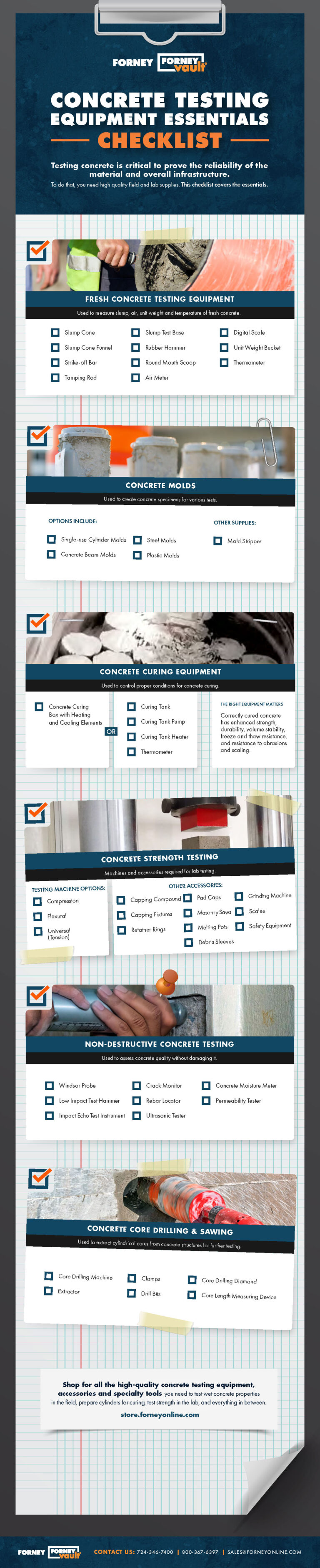

The durability and safety of every structure depend on a solid concrete foundation. Testing concrete mix design, strength and performance is critical to ensure the reliability of the material. To make it happen, you need at least these concrete testing equipment essentials.

At the construction site during the pouring process, technicians conduct field testing by sampling fresh concrete. At the lab, typically on days 3, 7 and 28, technicians will test concrete cylinders for strength. From the field to the lab and in between, there are many different categories of concrete testing equipment you will need:

- Fresh concrete testing equipment: used to measure slump, air, unit weight and temperature of fresh concrete.

- Concrete molds: used to create concrete specimens for various tests.

- Concrete curing equipment: used to control proper conditions for concrete curing.

- Strength testing equipment: machines and accessories required for lab testing.

- Non-destructive testing equipment: used to assess concrete quality without damaging it.

- Core drilling and sawing: used to extract cylindrical cores from concrete structures for further testing.

#1. Fresh Concrete Testing Equipment

Fresh concrete tests measure important wet concrete properties at the time of mixing and pouring, prior to curing. These tests are essential as they ensure the concrete mix has the right consistency and workability.

Tests include slump tests, air content tests, unit weight measurements, and temperature readings. Here’s a list of essential fresh concrete testing equipment:

- Slump cone

- Slump cone funnel

- Strike-off bar

- Tamping rod

- Slump test base

- Rubber hammer

- Round mouth scoop

- Air meter

- Digital scale

- Unit weight bucket

- Thermometer

#2. Concrete Molds

In the field, technicians will not only conduct the above fresh concrete tests but also prepare samples in various shapes and sizes – which requires molds.

Depending on your needs, you can use single-use cylinder molds, plastic molds, or steel molds. If you’re testing tensile strength, you will need concrete beam molds. Regardless of the form of your concrete mold, you will also need a mold stripper that allows you to remove molds from the specimen.

#3. Concrete Curing Equipment

Concrete curing is the process of keeping your concrete specimens at the proper moisture levels and temperature. Correctly cured concrete has enhanced strength, durability, volume stability, freeze and thaw resistance, and resistance to abrasions and scaling.

To properly cure concrete, you will need the right equipment, including:

- Concrete curing box with heating and cooling elements

- Curing tank

- Curing tank pump

- Curing tank heater

- Thermometer

#4. Concrete Strength Testing Equipment

Concrete strength testing typically occurs after 3, 7 and 28 days of curing. The most common lab test is called a compression test, which allows technicians to test concrete cylinders, cubes, blocks and prisms by pushing on the material until failure. Concrete strength can also be tested through a tension test, which pulls the specimen until it breaks, and a flexural test, when bends a specimen until it breaks.

In addition to material testing machines that serve your testing need, you will need a plethora of accessories, including:

- Capping compound and fixtures

- Retainer rings

- Pad caps

- Masonry saws

- Melting pots

- Debris sleeves

- Grinding machine

- Scales

- Safety equipment

Some of this equipment will come in handy when you’re still testing in the field and preparing specimens for curing. Others will help you get the concrete specimen ready for testing after curing. For example, it’s important to ensure that the ends of a concrete cylinder are uniform and parallel to each other prior to strength testing so the measured strength is not artificially diminished.

#5. Non-Destructive Concrete Testing Equipment

Traditional methods of concrete strength testing require extreme stress that will ruin the sample. Sometimes, you need interim tests that leave your material intact. To conduct these non-destructive tests, you will need pieces of equipment like:

- Windsor probe

- Low impact test hammers

- Crack monitors

- Impact echo test instruments

- Rebar locators

#6. Concrete Core Drilling & Sawing

While non-destructive concrete testing methods are ideal, sometimes you have to test concrete’s properties in an existing building or structure. This is called concrete coring. In order to measure carbonation, permeability, strength, chemical makeup, or other characteristics of concrete from a building, you will need concrete core testing equipment:

- Core drilling machines

- Extractors

- Clamps

- Drill bits

Conclusion

Testing concrete is critical to prove the reliability of the material and overall infrastructure. So, it’s just as critical to have high quality field and lab supplies.

With a good solution for regularly stocking up on your concrete testing essentials, your lab will be able to test more effectively and reliably.

Forney’s construction materials testing equipment has been trusted by thousands of construction companies and labs for over a hundred years. Shop now or tell us about your testing needs.