Materials must be tested at every step of the construction process—from mix design to core sampling. In this blog, we provide an overview of four major types of testing machines that are capable of testing a wide variety of specimens.

Construction material testing (CMT) machines play a pivotal role. Without them, project owners and engineers have no way of knowing if the quality of the materials used in their building projects meets expected requirements. Finding the right machine for your needs depends on a variety of factors, including:

- The material you need to test

- The specimen’s geometry

- The type of test you need to perform

In this blog, we will explore these factors and provide an overview of the four main types of material testing machines.

Types of Materials, Geometries & Tests

Many materials must be tested in a construction project, from concrete and cement to metals and plastics. Here are some of the most common:

- Concrete

- Mortar

- Grout

- Self-consolidating concrete

- Metals

- Plastics

- Hydraulic cement

- Down hold cement

- CLSM/Flowable fill

- Proppant Ceramics

Material matters, but so does the specimen geometry (AKA the shape of the specimen or coupon your testing). Geometries can be defined as:

- Cylinders

- Cubes

- Grout Prisms

- Beams

- Masonry Blocks

- Masonry Prisms

- Rock Core

- Rebar

- Screws

- Bolts

- Wire

- Bars

- Coupons

Lastly, there are several different types of tests that you might need to perform. Here is a brief description of the major types:

- Compression: Pushing on a specimen until it breaks

- Tension: Pulling a specimen until it breaks

- Flexural: Bending a specimen, which produces tensile stress on the outside of the bend (convex face) and compressive stress on the inside of the bend (concave face), until it breaks

- Modulus of Elasticity (MOE): Measures the resistance to deformation – how much does it stretch/compress in response to a given force

- Poisson’s Ratio: Similar to MOE, measures the resistance to deformation perpendicular to the direction of the load

- Tensile Splitting: Loading a test specimen cylinder lying on its side and splitting its diameter vertically as an indirect method of determining its tensile strength

So, with so many factors at play, how do you know what type of equipment you need to get the tests done? Luckily, these four types of material testing machines cover almost every testing need.

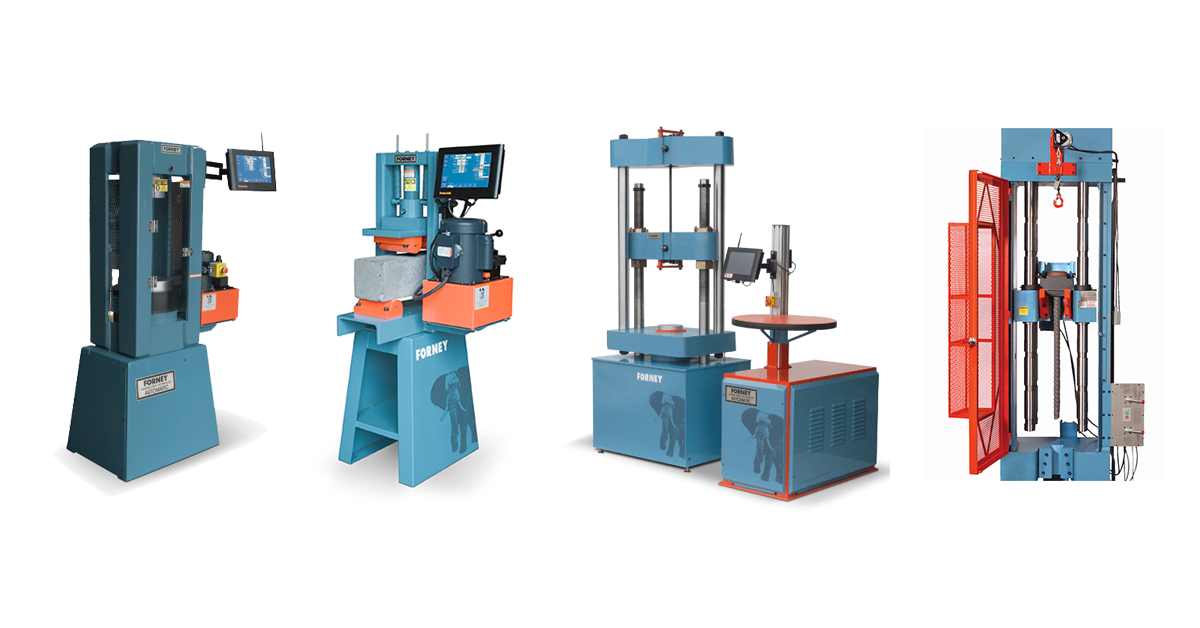

4 Types of Material Testing Machines

All of the following material testing machine types can be configured to your exact specifications and adhere to ASTM, AASHTO, ISO, API, BS and EN protocol standards.

1. Compression Testing Machines

Compression testing is fundamental to determining strength characteristics of materials.

Compression testing machines are commonly used for high-strength concrete cylinder testing. However, you can also test cubes, beams, blocks, prisms and bulk fines of many other materials.

Compression testing machines can be used in the lab and the field and are available in a variety of frames with a range of load capacities. In addition to compressive strength, you can also run tests for Modulus of Elasticity/Poisson’s Ratio, and Tensile Splitting.

Standard compression machines are versatile, durable and dependable for conventional testing environments. In more demanding testing environments, high stiffness or high-capacity machines may be necessary. These are designed for larger specimens and/or high strength materials, with rigid welded steel frames. Load capacities can exceed 1Mlbf.

2. Flexural Testing Machines

Flexural testing machines are versatile and ideal for testing concrete as used in highways and airport runways.

Just like compression machines, you can use these in the field or the lab. In fact, some manufacturers can provide a flexural frame that you can attach to a compression machine—an economical solution that covers several needs at once.

With a flexural testing machine, you can test for beam flexure or strength in materials with failure below 30,000lbf., like grout, pavers and cubes.

In addition to flexure and strength, these testing machines are capable of testing for Modulus of Elasticity/Poisson’s Ratio, Proppant Crush Resistance and Tensile Splitting.

3. Universal Testing Machines

Universal testing machines are just that: universal, multi-purpose testers. You can measure and control via a variety of axes and vector types—force, pressure, stress, strain and low-range force, in compression, tension or bending.

From cylinders and cubes to bolts and wire, test a wide array of specimens and materials (cementitious, non-cementitious, metallic, non-metallic), measuring force, displacement, velocity and strain. Test according to desired methods in capacities of 20,000 – 850,000lbf.

4. Specialty Testing Machines

While the previously listed machines can solve many of your testing challenges, sometimes you need something unique and custom that solves for a special application.

You can work with a manufacturer to develop a machine that delivers a practical and cost-effective solution to satisfy specific testing requirements and determine specialized material or product properties.

For example, Forney has worked with professionals to develop concrete railroad tie testers, proppant testers for hydraulic fracturing sand, tile and paver testers, machines to test bolts, ball bearings and more.

Manual or Automatic?

All of the above machine types are available as manual or automatic control.

But manual machines can be inefficient and highly variable depending on the skill level of the operator. That’s why more and more testing organizations are moving to automatic control systems to bring better accuracy, consistency and repeatability to the testing process.

Automatic controls provide automatic preloading and rate adjustments, energy-efficient hydraulics and more. This helps busy machine operators save time and let tests run on autopilot without impacting the quality of results.

And it doesn’t matter if you already have a manual machine. You can often upgrade your controls to automatic.

One More Thing: The Machine Manufacturer Matters

Buying material testing machines is a big investment. So, it’s important you buy from a reputable manufacturer.

When you’re looking for a machine, make sure the manufacturer promises the following qualities:

- Repeatable and precise results

The integrity of the machine’s frame needs to exceed requirements and the design and manufacturing of the machine need to be top-notch to ensure continued and repeatable results over years of use.

- Safety of technicians and machines

The safety of lab technicians and service personnel is paramount. Machines should be designed with the operator in mind, regardless of skill level.

- Ease of use

Ergonomic design and thoughtful details should ensure easy testing, even for new technicians.

- Customer support

You know you have a good machine if it’s built and backed by an expert technical support team that knows the industry well. If you want your machine to last, work with a manufacturer that offers a dedicated team of engineers and technicians with years of experience with your equipment. So, you can trust that any problems that come up will be dealt with properly and in a timely manner.

Conclusion

With so many testing requirements, materials, specimen geometries and regulatory protocols to consider, it can be difficult to figure out what machine works best for your needs. Use our Machine Finder tool to help narrow down your search.

Forney is the Original Testing Machine, representing the standard in CMT. Find yours today.