Engineered composite ties are an essential innovation for our railway system. Most often manufactured from recycled plastics, they present a sustainable – and more reliable – option over wooden ties.

In a world challenged by single-use plastics, composite rail ties can provide a path to circularity. The industry has long struggled with finding an alternative to wooden ties, which fail at less than their economic life due to wear and tear, weather and insect infestation. Not to mention the quantity of trees that have to be cut down to replace them each year, or the poisonous creosote that’s used to treat them.

Today, the railroad industry has a true composite that outperforms the wooden tie and other poorly engineered alternatives. But to drive faith in the material and uphold safety standards, these ties need to be tested according to AREMA standards.

The American Railway Engineering and Maintenance-of-Way Association (AREMA) is a North American railway industry group that publishes recommended practices for the design, construction and maintenance of railway infrastructure in the United States and Canada.

In this post, we will discuss the minimum performance requirements for engineered composite ties as specified by AREMA Chapter 30, which provides guidance for the design, manufacture and use of engineered composite ties and their components. It also covers the materials, physical dimensions, physical properties and structural strength of engineered composite ties.

What Are Engineered Composite Ties?

Engineered composite ties are a relatively new technology that help mainline standard gauge railway ballasted track systems function properly. The composite tie transfers loads to the track ballast and subgrade, holds the rails upright and keeps them spaced to the correct gauge. Today, engineered composite ties are made from polymer composites and engineered wood products. In the past, ties were conventionally made with sawn wood, concrete and steel.

Proper testing of engineered composite ties is essential to ensure they meet all AREMA requirements.

Getting Started with AREMA Chapter 30

AREMA Chapter 30 provides the following dimensional requirements for engineered composite ties:

- Tie surface flatness in the tie plate area must be within 3.18 mm

- Standard ties must be within 7” x 9” and 8.5’ to 9’ long

- Rail-bearing areas are the sections between 20” and 40” from the center of the tie

What Lab Tests Need to Be Done for AREMA Chapter 30?

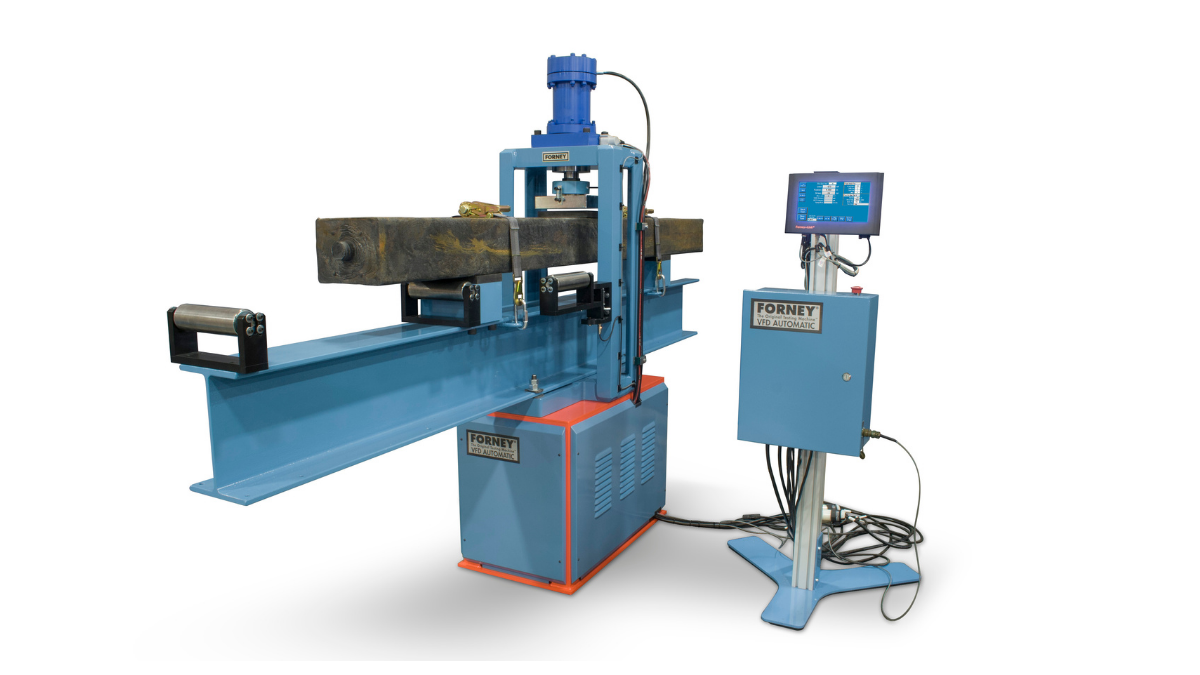

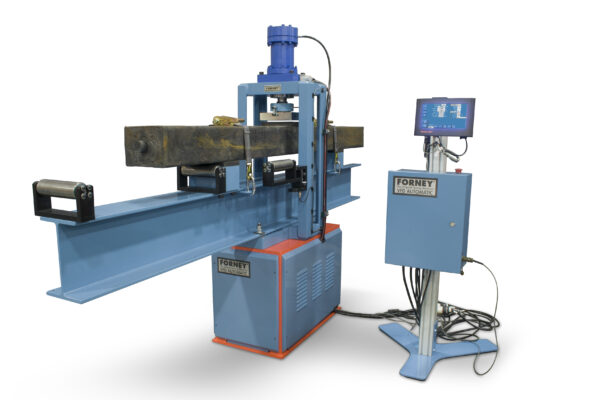

To properly test engineered composite ties, a number of lab tests are required. Forney’s LA-300-VFD Railroad Tie Tester can streamline testing for engineered composite ties using standardized testing protocols. A cost-effective machine, the LA-300-VFD can be leveraged in the QA role of a production facility to ensure quality manufacturing of composite rail ties.

This type of specialty machine completes the required testing for engineered composite ties and confirms or denies if certain material properties are compliant with AREMA standards. In this post, we cover one specific test that this machine can complete. Please be sure to refer to AREMA Chapter 30 for detailed test information and additional tests that need to be completed.

Center Negative Bending

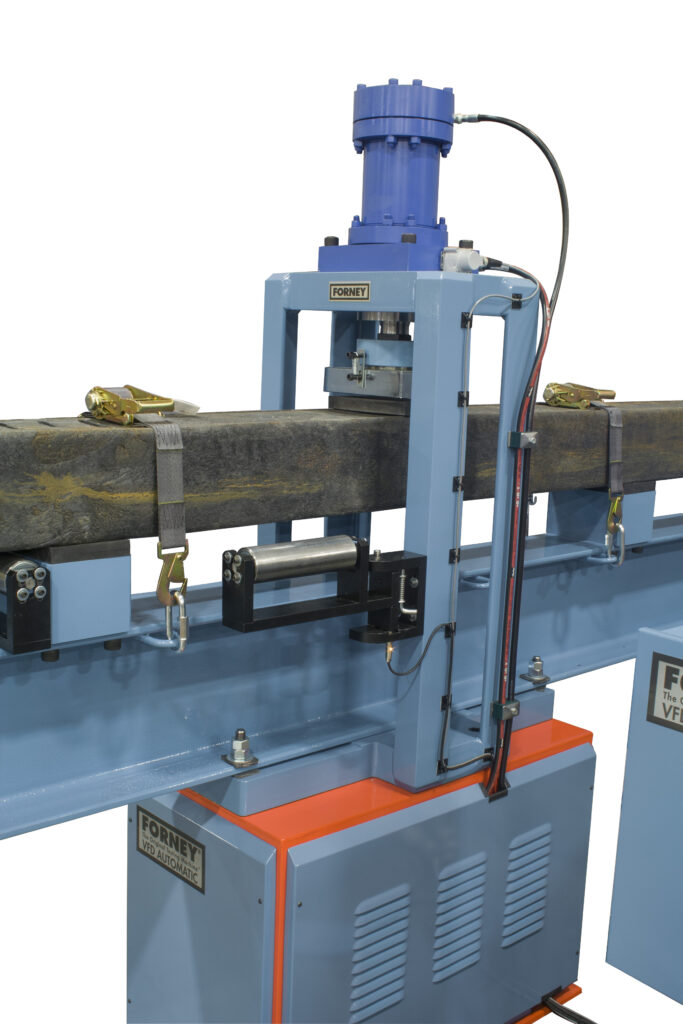

The center negative bending test – guided by the test method found in Part 2, Section 2.2.3, Test 1C of AREMA Chapter 30 – determines center negative flexural bending performance. For engineered composite ties, the load must be applied at a deflection rate of five inches per minute.

This test measures the modulus of elasticity (MOE) and modulus of rupture (MOR) in engineered composite ties.

MOE describes the bending stiffness of the tie, used as an indicator of manufacturing consistency. The recommended value is typically between 150,000 and 250,000 psi.

MOR is a measure of the ultimate bending strength of the tie. It indicates the performance of the tie under repeated bending stresses. The minimum recommended value is 2,500 psi.

Test Results

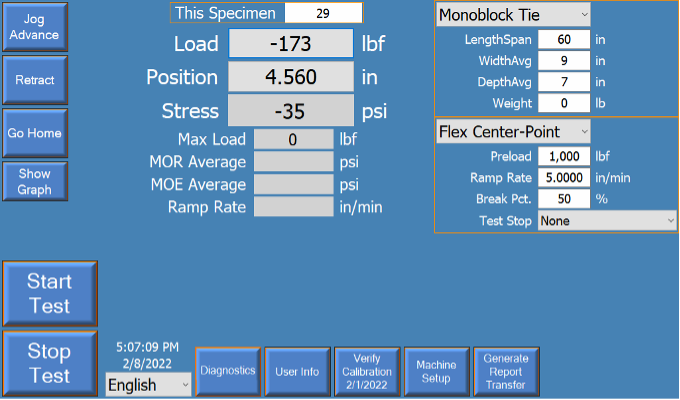

With Forney’s LA-300-VFD Railroad Tie Tester, you will receive test results quickly and accurately at the machine, which can then be exported as a PDF report.

This versatile machine is easy to use but maintains critical regulations that guide engineers to make the right decisions. Test data is readily available right from the ForneyLink HMI, so you don’t have to manually record any information. Simply save, print and share.

Conclusion

The tests performed on engineered composite railway ties are crucial to ensuring that all structural requirements and safety regulations are met – especially pertinent as the failure of other substitutes dampened the industry’s confidence in finding an alternative to wood.

Need to test engineered composite ties? Contact us to learn if LA-300 VFD is right for you – or we can design a machine that meets your unique needs.