Grout is a cementitious construction material used to fill space and create a solid connection between masonry units. To enhance the structural integrity and functional properties of the masonry, grout must meet precise quality criteria.

In this article, we walk through the ASTM C1019-20 test method: sampling and testing the compressive strength of the grout. We cover:

- Introduction to ASTM C1019-20

- Recommended CMT supplies and equipment

- How to properly follow ASTM C1019-20

Introduction to ASTM C1019-20

Grout is a substance that provides a pourable consistency for cement material. Typically made from a mixture of cement, water and additives, grout is used in construction to enhance structural integrity and load distribution of a masonry wall. It’s placed either between masonry units or within them to reinforce the material.

ASTM C1019 covers the standard method for field and laboratory grout compression testing. It can be used to optimize grout properties before construction or for quality control purposes during construction. There are two main components of the test:

- Sampling the grout by creating masonry grout prisms

- Testing the grout strength by applying compressive pressure to the test specimen

Here’s what you will need to do both.

Recommended Equipment for ASTM C1019-20

Sampling Grout

The grout sample used to create specimens should duplicate the grout used in construction. That means the sample should be taken after any adjustments for slump are complete.

In the field, a sample is made up of two or more portions of grout captured at regular intervals during discharge of the middle third of the batch. These portions should be remixed with a shovel or trowel before molding specimens.

Molding Masonry Grout Prisms

In construction, grout has high water content so it flows easily within masonry units. The excess water is absorbed by the masonry units, allowing the grout to achieve its desired strength.

Masonry grout prisms are test specimens that are formed from a grout sample. The ASTM C1019-20 test method requires specimens to be molded from masonry units that are the same type and moisture condition as those used in the actual construction. The specimens prepared via this test method will not exactly reproduce the exposure and curing of the grout in construction, but the conditions will be similar.

The specimens are created by forming molds out of masonry units so that the conditions simulate the actual construction. If two different types of masonry units are used in the construction (i.e., brick and concrete masonry units), then those two types need to be used for the molds. There are several diagrams available for different scenarios.

The test method does provide an alternative to creating molds out of masonry units, but these methods must be compared to masonry molds to prove that they produce the same results, and they must be approved by the specifier. If approved for this approach, you will need:

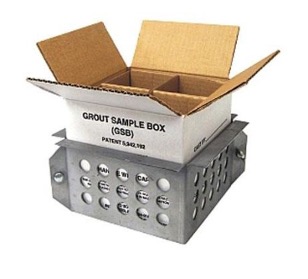

- Grout sample box that acts as a mold and transport container for your test specimens. This is an alternative to the traditional method of concrete masonry units (CMU), simulating CMU absorption rates and retaining moisture with slotted corrugated cardboard. This single-use box yields comparable compressive strength values at a fraction of the cost and time.

- Grout sample box fixture that provides support of the grout sample box sidewall, which helps to maintain the squareness and consistency of each of the four individual specimens.

Testing Grout Strength

When it’s time to test the grout prism in the lab, you will need:

- Grout prism capping stand that makes it easier to center and maintain perpendicularity while capping your test specimen.

- Grout sample pad caps and capping retainers.

- Caliper: A tool to measure the dimensions of the prism before and after testing, which is crucial for calculating cross-sectional area.

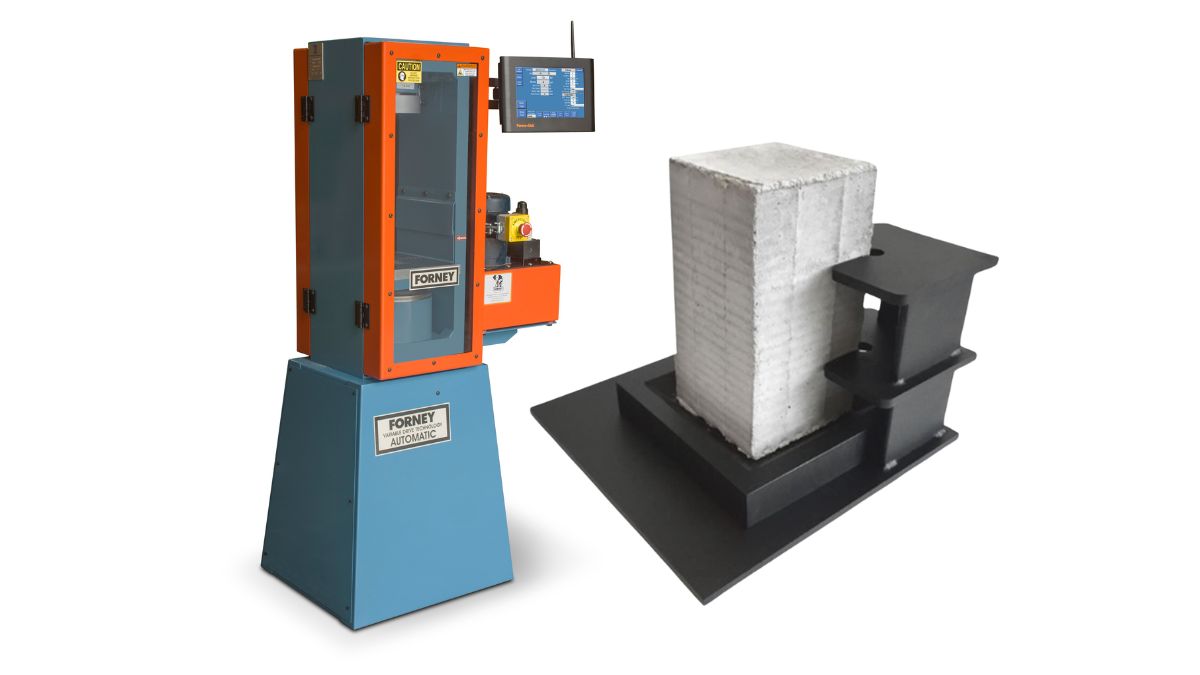

- Compression test machine: A machine that applies compressive pressure to the grout prism using platens to determine the material’s behavior under applied crushing loads.

- Data acquisition system: A reliable method of capturing and reporting data as you perform the test.

ASTM C1019-20 Test Procedure & Results

Test Procedure

- Form grout specimens in grout sample box or CMU according to ASTM C1019. The grout mold must have the same absorption and moisture content characteristics as the grout in the wall.

- Rod each layer of the grout 15 times to eliminate air bubbles and level the top of the specimen with a straight edge.

- Cover specimen with damp material for initial curing.

- Let specimens sit for 24-48 hours, protected from temperature extremes to promote curing.

- Remove molds and store in a moist room, cabinet or tank for curing prior to testing. The test age is determined by the specifier of the test , but it is typically 7 or 28 days.

- Measure specimen width, height and out-of-plumb. If a specimen doesn’t meet the minimum requirements for height-to-width ratio, it can be cut, ground, or capped to meet the requirement. If the tolerances cannot be met, the specimen should not be tested.

- Cap specimens in accordance with ASTM C617.

- Test compressive strength according to ASTM C39. Center the grout prism on the compression testing machine’s lower platen. Apply a gradual compressive load to the specimen at a constant rate of 35 psi/s ± 7 psi/s (0.25 MPa/s ±05 MPa/s) until the specimen fails.

Test Results

- Record maximum load value of each specimen.

- Calculate cross-sectional area of the grout prism with measured pre-test dimensions.

- Calculate compressive strength by dividing the maximum load by the cross-sectional area.

- Note the type and number of masonry units used to form the mold when masonry units are used.

- Describe the method used, conversion factor, average corrected compressive strength, and coefficient of variation of the compressive strengths when alternative methods of forming are used.

Technicians can get more done faster with minimal human error with a Connected Compression Machine. Connected machines are integrated with CMT software, offering pre-test “Smart Checks” to validate test parameters, automatic preload calculations, and automatic test controls. At the end of the test, values are automatically calculated and transferred via private cloud to your LIMS or software of choice. As the machine captures and calculates values for you, you can focus on cleaning and preparing the next specimen for testing.

Conclusion

Testing grout compressive strength is an important part of using masonry in construction. Before performing ASTM C1019-20, please be sure to use the current ASTM standard.

Questions about performing ASTM C1019-20? Need concrete grout testing equipment or supplies? Explore the store here or contact us for help.