Aggregate gradation is a foundational testing parameter that informs the strength, durability, and workability of a particular mix of concrete. ASTM C136 provides a standardized method for determining the particle size distribution of fine and coarse aggregates. Properly balanced gradation ensures that concrete mixes are made to last, can perform as designed, and meet exact project specifications.

In this guide, we simplify ASTM C136 to help materials testers quickly grasp:

- The Importance of ASTM C136

- Recommended Equipment

- ASTM C136 Test Preparation & Procedure

- Results & Reporting

The Importance of ASTM C136 for Materials Testing

Aggregate gradation is a measurement that captures the distribution of particle sizes in a sample of aggregate. A well-graded aggregate has a balanced mix of particle sizes that can disperse in a way that minimizes integrity issues and maximizes packing density. Poor gradation can cause segregation, bleeding, honeycombing (the formation of voids), or generally weak concrete.

A sieve analysis following ASTM C136 determines the percentage of material retained on or passing through sieves with progressively smaller openings. Subsequent calculations guide:

- Concrete Mix Design: Achieves target workability, strength, stability, and durability.

- Quality Control: Confirms consistency between aggregate batches and sources.

- Specification Compliance: Ensures AASHTO Standard T27 (Sieve Analysis of Fine and Coarse Aggregates) and project requirements are met.

When it comes to the longevity of construction projects, controlling the production of materials to perform consistently and successfully under pressure is crucial. To make calculations according to ASTM C136, testers need the following equipment.

Recommended Equipment

Standard test sieves with suitable openings and frame-mounted cloth conforming to ASTM E11 (Specification for Woven Wire Test Sieve Cloth and Test Sieves), with pans and covers.

When the size of the sample is 20kg or greater, a mechanical sieve shaker is advised to agitate the stack uniformly. It may also be used for smaller samples, including fine aggregate.

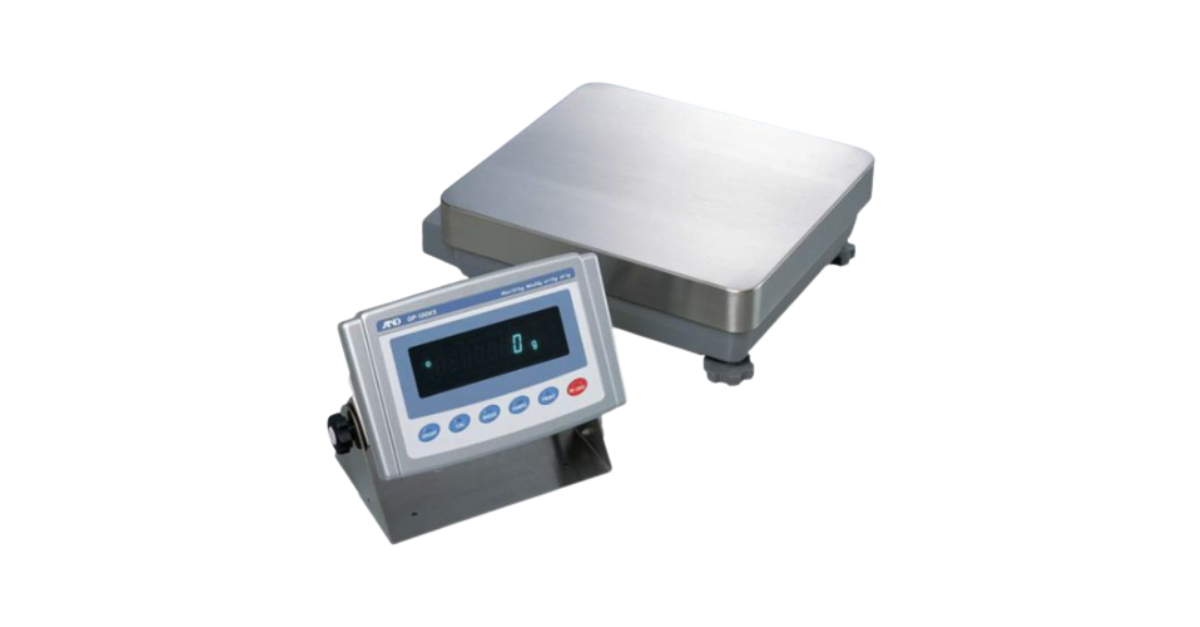

A balance or scale with proper readability and accuracy as follows:

- For fine aggregate: readable to 0.1g and accurate to 0.1 g or 0.1 % of the test load — whichever is greater at any point within the range of use.

- For coarse aggregate, or mixtures combining the two aggregate types: readable and accurate to 0.5g or 0.1% of the test load — whichever is greater at any point within the range of use.

An oven of the appropriate size and capable of maintaining 110 ± 5 °C (230 ± 10 °F).

A riffle sample splitter to reduce samples.

A brush and a rubber mallet to clean sieves without damaging mesh.

A timer to ensure consistent shaking durations.

ASTM C136 Test Preparation

To follow ASTM C136, aggregate samples must first be prepared and mixed in accordance with:

- ASTM D75 (Practice for Sampling Aggregates)

- ASTM C702 (Practice for Reducing Samples of Aggregate to Testing Size)

- ASTM C117 (Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing)

- ASTM C670 (Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials)

Sample Preparation

Identify test sieves with suitable openings for aggregate types conforming to ASTM E11 (Specification for Woven Wire Test Sieve Cloth and Test Sieves). Sieves mounted in frames larger than the standard 203.2-mm [8-in.] diameter should be used for testing coarse aggregate to reduce the possibility of overloading the sieves.

Prepare a representative aggregate sample per ASTM D75 (Practice for Sampling Aggregates) quantity specifications or four times the nominal maximum size of the following aggregate types, whichever is greater.

- For fine aggregate, the size of the test sample after drying should be minimum 300-g.

- For coarse aggregate or fine and coarse aggregate mixtures, the sample size should conform to the requirements of Table 7.4 in ASTM C136.

- The size of a sample required for larger size coarse aggregate (50-mm [2-in.] nominal maximum size or larger) should be no less than 20kg.

Procedure

#1 Mix, Dry, & Reduce

- Thoroughly mix the sample.

- Dry the sample in the oven to constant mass at a temperature of 110 ± 5°C [230 ± 10°F].

- Using a riffle splitter to reduce the sample to a suitable test size amount, as described in ASTM C702 (Practice for Reducing Samples of Aggregate to Testing Size).

#2 Weigh & Record

- Weigh the dried sample to the nearest 0.1 g (initial mass). The fully dried test sample should amount to the desired quantity.

#3 Assemble Sieve Stack

- Arrange sieves in order of decreasing size of opening from top to bottom and place a pan underneath.

- For opening sizes larger than the 4.75-mm (No. 4) sieve, limit the material on the sieve to a single layer of particles.

- Load the aggregate onto the top sieve, limiting the amount of material so that all particles can reach sieve openings a number of times during the test.

- Place the snug-fitting cover on top.

#4 Sieve the Sample

- Manually agitate the smallest sieve by holding it in a slightly inclined position in one hand and striking the side with a sharp, upward motion against the heel of the other hand at a rate of about 150 times per minute. At 25 stroke intervals, turn the sieve about 1/6 of a revolution. Continue to agitate until not more than 1% by mass of the material retained on any individual sieve will pass that sieve during 1 minute of continuous hand sieving.

- If the size of the mounted testing sieves makes the hand sieving motion impractical, use 203-mm [8-in.] diameter sieves to verify sufficiency.

- Alternatively, use the mechanical sieve shaker.

- For aggregates with a nominal maximum size of 12.5-mm [1/2-in.] or less, test the sample in accordance with ASTM C117 (Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing) through the final drying operation, then dry sieve the sample as stipulated in 8.2 – 8.7 of ASTM C136.

#5 Weigh Retained Material

- Carefully brush and tap each sieve with the soft mallet to collect all retained particles.

- Weigh the material retained on each sieve on a scale or balance and record the mass to the nearest 0.1% of the total original dry sample mass.

- If the amounts differ by more than 0.3%, do not use the results for acceptance.

- Since the mass retained on each sieve is recorded to the nearest 0.1% of the total mass, the mass could vary by as much as 0.1% times the total number of recorded mass values. If seven sieves are weighed, there could be a difference of 0.7%. Any difference higher than this should be investigated. As stated above, if there is a difference of more than 0.3%, do not use the results for acceptance of the material.

- An alternative method is to weigh each sieve empty (i.e., the tare weight), weigh the full sieve, and then subtract the tare weight from the full weight to determine the mass of the material. Sometimes, it is difficult to remove all of the material from the sieve without washing, so this method does not require careful removal.

Results & Reporting

To calculate the aggregate gradation, compare the total mass of the material to the initial mass. Determine the percentages retained and cumulative passing percentages for each sieve size in various size fractions to the nearest 0.1% on the basis of the initial dry sample mass.

With these values, testers can plot the gradation curve (if required by specifications), confirm compliance, or refine the mix design for optimal performance.

Due to the inconsistent nature and timing of the agitation that ASTM C136 requires — and the manual calculations involved — the traditional sieve analysis process is prone to errors. The solution? ForneyVault’s new Automated Sieve Analysis Platform.

Testers can now automate aggregate workflows with this digital software and adhere more closely to procedure. It provides instant access to comprehensive, professional reports, and even plots particle size distribution data in the gradation curve against the required upper and lower limits, so there is immediate visual confirmation of compliance within project specifications.

Every critical data point required by ASTM C136 is captured digitally, ensuring there is a complete and auditable test record:

Project & Sample Information

- Project Name & Number

- Client & Supplier

- Sample ID & Location

- Material Type

Sieve Inventory

- Unique Sieve ID (Barcode Ready)

- Nominal Sieve Size

- Calibrated Tare Weight

- Calibration Date & Status

Test Parameters

- Initial Dry Mass

- Total Mass (Sieve + Retained)

- Mass Retained (Auto-Calculated)

- Wash Test (ASTM C117) Data

This new software not only eliminates data inaccuracy, but ultimately guarantees higher-quality tracking of aggregate gradations. Powerful management modules reduce setup time and standardize testing and calculation procedures across the entire lab, improving productivity and reliability throughout the ASTM C136 test method.

Conclusion

ASTM C136 is a fundamental test method for measuring the aggregate gradation of construction materials. Before performing ASTM C136, please be sure to reference the current ASTM standard.

Forney has the specialty sieve shakers, related accessories, and integrated software to display real-time data for ASTM C136 testing. Shop the Forney store today or explore the Digital Sieve Analysis Platform — which can be run on its own for aggregate-only operations, or inside your existing ForneyVault environment.