The lightweight nature and high tensile strength of polymer matrix composite materials make them the perfect substitute for metals in many applications, especially the aerospace and automotive industries.

But before we can use these composite materials with confidence, we have to rigorously test them — which is where ASTM D3039 comes in. Let’s take a deeper look.

What Are Polymer Matrix Composite Materials?

A polymer matrix composite (PMC) is a composite material made of short or continuous fibers bound together by a matrix of polymers. Its matrix makes it possible to transfer loads between the fibers.

This type of composite is beneficial to nearly all aspects of modern life, from household gadgets to automotive accessories. The two main types of polymer composite matrix materials are thermoplastics and thermosetting resins.

PMC materials are also commonly referred to as Fiber Reinforced Polymers (FRP), Fiber Reinforced Composites (FRC), and several other names.

Getting Started with ASTM D3039

This test, developed by ASTM International, is the process of applying a tensile force to a specimen and then assessing how the specimen reacts under stress. There are several tensile properties that ASTM D3039 evaluates:

- Tensile strength: the most stress applied to the specimen during the test.

- Ultimate tensile strain: the strain on the specimen when it breaks.

- Tensile modulus: the way the specimen stretches while under stress.

- Poisson’s ratio: the ratio of expansion along one axis to contraction along the opposite axis.

- Transition strain: the strain value when change occurs.

- Failure mode: a three-character code is given to broken specimens based on their failure type, area and location.

This data produced from this test is critical to quantify composite strength for research and development and quality assurance purposes.

Recommended Equipment

There are several types of equipment that are recommended for this particular test. Forney offers the appropriate machine and each piece of equipment that is required for ASTM D3039.

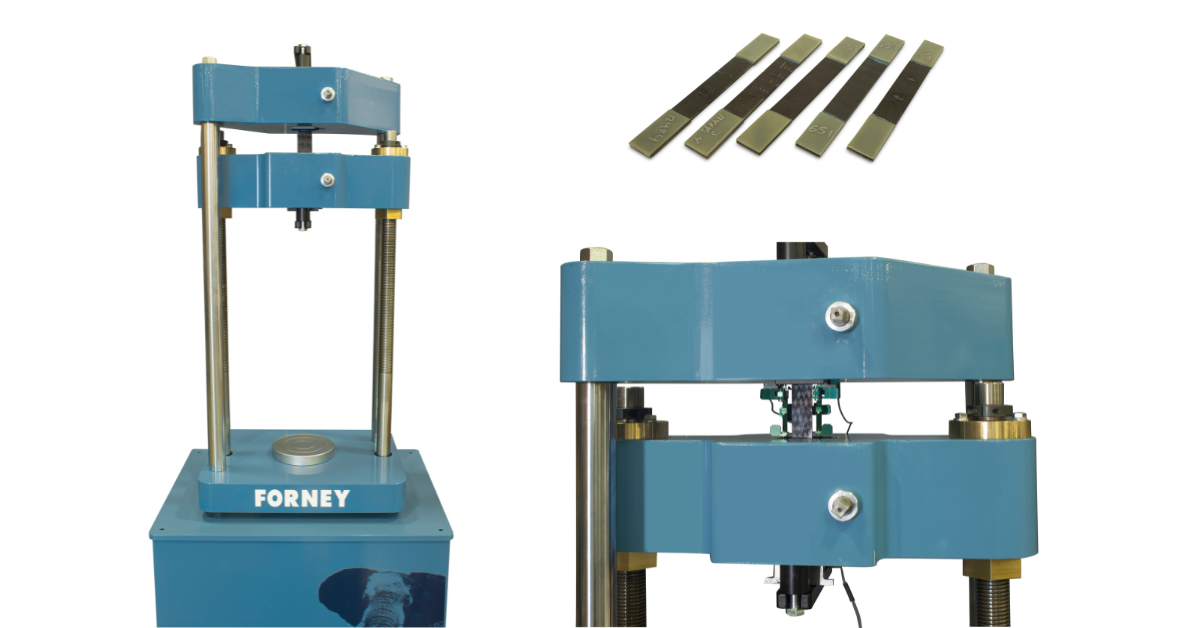

Materials Testing System

ASTM D3039 requires a tabletop or floor model universal testing machine. A 30 kN or 50 kN system is typically sufficient for testing glass composites, but a 100 kN or 250 kN system is required for testing carbon composites.

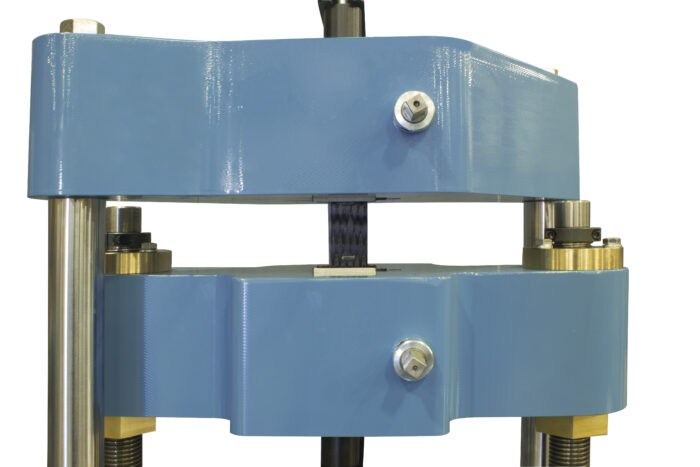

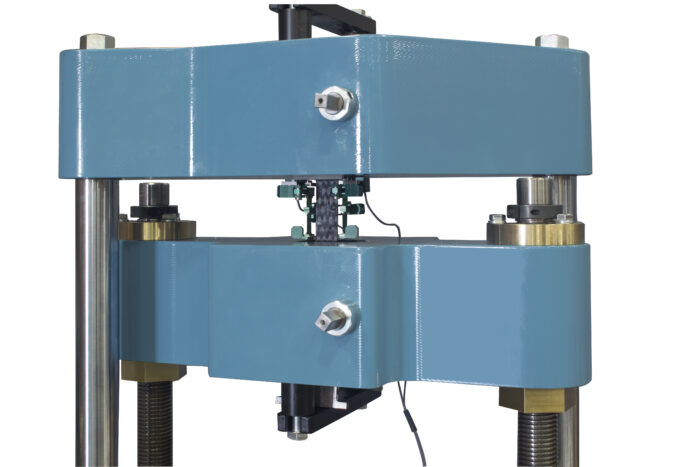

Grips and Specimen Alignment

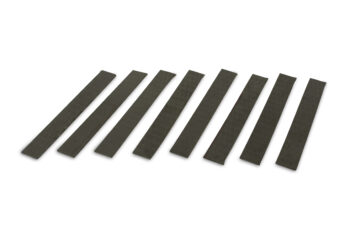

Sufficient grips are needed to perform this test.

In order to hold composite specimens, grips need to be strong, suitable for the material and in good condition. The ASTM C3039 standard provides guidance for gripping specimens but acknowledges that there is no industry consensus as to the preferred gripping interface. The alignment of the grips and the specimen within the grips should keep the bending strain to within 3-5% at moderate strain levels.

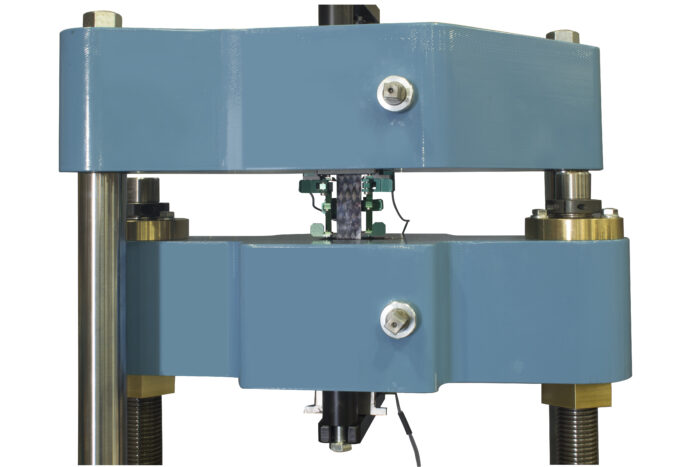

Extensometers

Extensometers are the most common devices used to measure strain during the ASTM D3039 test. The size and type of a required extensometer depend on your laboratory needs, although most clip-on extensometers are sufficient.

It is important to note that when testing for Poisson’s ratio, a transverse extensometer must be used to measure the change in width throughout the elastic region of the specimen.

In some situations, the PMCs being tested are meant to be used in non-ambient conditions. To mimic these end-use scenarios, ASTM D3039 can be performed inside a chamber where heating and cooling can be implemented. This impacts the type of extensometers that can be used during the test, as they can’t all be used in the same temperature range. Most clip-on extensometers can be used up to a maximum temperature of 200 °C, and if the temperature must go beyond this number, a non-contacting advanced video extensometer can be used — this is mounted outside of the chamber and uses a camera to monitor the specimen throughout the test.

Strain Gauges

Bonded resistance strain gauges are also common devices to measure strain during ASTM D3039. Because they can be used in environmental conditions that go beyond 200 °C, they can replace extensometers. However, several factors must be considered during selection of bonded strain gauges. High excitation voltages or low resistance strain gauges can heat the specimen in the location of the gauge, affecting performance of the specimen. Temperature compensation of the strain gauges is also important – and required when using an environmental test chamber.

Testing Chamber

Appropriate testing chambers need to have the ability to achieve both high and low temperatures. This means they might need forced air convection, liquid nitrogen or carbon dioxide.

ASTM D3039 Test Control & Procedure

Test Control

The ASTM D3039 procedure should be conducted at a constant crosshead speed, and testing requirements state that the test should always produce a failure within one to 10 minutes. A single sample needs to be tested five times before reaching an accurate result.

Test Procedure

- Prepare testing chamber (if used) and set to required conditions based on your unique test.

- Attach bonded strain gauges, if used.

- Mount the material onto the grips of a mechanical testing machine using.

- Mount extensometer(s), if used.

- Complete five tests for each sample.

- Record all success and failure with the appropriate codes.

Calculating Test Results

ASTM D3039 requires a lot of moving parts and calculations to get the necessary strength information. Because of this, manual calculations and testing are vulnerable to human error – and they can take a long time.

An automatic universal testing machine combined with an integrated CMT platform will help you get the results you need right away – without the tedious calculations. At test completion, values are automatically displayed and transferred to a secure, private cloud database for immediate analysis.

Conclusion

The ASTM D3039 test is vital to those who use PMCs in their industry applications. Before performing ASTM D3039, please be sure to use the current ASTM standard.

Do you have questions about performing the ASTM D3039? Contact us for all your needs.