According to ASTM D7012, there are a number of ways a geotechnical and construction materials testing organization should test intact rock core specimens—an essential step for any construction project that helps determine whether the ground can withstand the weight of the structure.

What Are Intact Rock Core Specimens?

Intact rock core specimens are cylindrical samples of sediment or rock drilled from the ground. Labs need to test intact rock core that is representative of the true strength of the ground intended for the structure, which means the specimens must represent the original rock formation. This requires sampling the proper dimensions:

- Minimum diameter: 47 millimeters (mm)

- Size: 10 times larger than the biggest mineral grain

- Length to diameter ratio (L/D): 2.0 – 2.5

Before testing, the lab needs to level the rock core specimen’s cylindrical ends within a 0.02 mm tolerance and not stray from perpendicularity by more than 0.06 degrees.

Construction materials testing labs can follow two ASTM D7012 methods to test compressive strength and modulus of elasticity (MOE). In this post, we explain the necessary testing equipment and steps you need to take to verify the integrity of your intact rock core specimens.

Getting Started With ASTM D7012

ASTM International is a globally recognized organization that develops and delivers testing standards. It first issued ASTM D7012 in 2004. The standard was derived from the need to streamline multiple standards for testing intact rock core specimens. In this guide, we will be looking at two of the four methods:

- Method C: Uniaxial Compressive Strength of Intact Rock Core Specimens (previously ASTM D2938)

- Method D: Elastic Moduli of Intact Rock Core Specimens in Uniaxial Compression (previously ASTM D3148)

Together, Methods C and D determine the unconfined, uniaxial strength.

Lab technicians perform uniaxial compression tests to determine a rock core specimen’s unconfined compressive strength (UCS). In a compression test, a load pushes on a specimen until it breaks to determine strength.

At the same time as testing UCS, the tester can also measure axial and lateral deformation to determine the rock core’s MOE and Poisson’s Ratio, which measures the resistance to deformation in response to a given force.

It’s important to test more than just UCS because the original rock mass’s strength is also affected by factors like discontinuities, faults and weathering. (That’s also why you need to perform ASTM D7012 on at least five rock core samples.)

Here’s what you’ll need.

Recommended Equipment for Testing Intact Rock Core Specimens

To test the compressive strength and elastic moduli of intact rock core specimens, you need four pieces of equipment:

- Loading device

- Platens

- Strain measurement devices

- Compression machine

The loading device, platens and strain measurement devices all make up an apparatus used to test for UCS.

Loading Device

Your loading device needs to apply consistent pressure at the required rate until the test is complete. It should also be able to perform stress- or strain-controlled tests.

Platens

You need two steel platens made with a minimum Rockwell hardness of 58 to transfer the axial stress applied by the loading device to the rock core specimen. At a minimum, the platens’ diameter must be the same as the sample’s diameter and have a thickness-to-diameter ratio of at least 1:2.

Strain Measurement Devices

The apparatus also needs strain measurement devices that measure axial and lateral deformations. Examples of strain measurement devices include:

- Linear variable differential transformers (LVDTs)

- Compressometers

- Electrical resistance strain gages

The D7012 standard has strict requirements concerning the resolution and accuracy of these devices. In addition, since strain is measured through failure of the specimen, these devices need to be able to survive what could be a violent failure of the specimen.

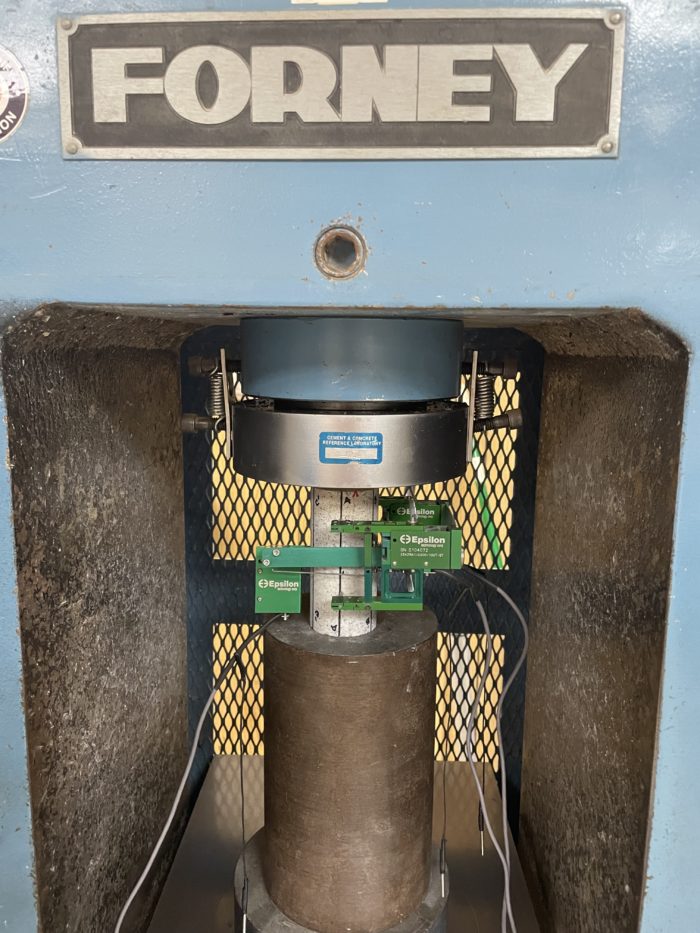

Compression Machine

Finally, you need a testing machine/system that can support ASTM D7012. Forney supplies the 250 Series, a versatile and ACI-exceeding compression machine with automatic controls. The frames are manufactured from solid steel into a one-piece, welded unit that allows it to handle any rock core specimen that comes your way.

It features:

- Heavy-duty frame

- Spherically seated upper platen held by calibrated springs and fixed on the compression machine piston head by the threaded pin

- Lower platen centered on the frame base

The machine’s structure is suitable for high-strength rock core specimens with brittle properties and explosive failures. For example, most geotechnical testing machines can’t test limestone because it exceeds the capacity of those machines—but Forney’s 250 Series can.

Once you have the right equipment to perform ASTM D7012, it’s time to get the sample and start the procedure. Here’s how it works.

ASTM D7012 Test Procedure & Results

Test Procedure

- Carefully clean the two platens before placing the specimen in the testing chamber.

- Continuously apply the load at a rate of 0.5 millipascal per second (MPa/s) to 1.0 MPa/s. With Forney’s 250 Series, this happens automatically and without error or variance.

- Failure should occur between 2 and 15 minutes.

- Record stress and deformation data through an electronic system meeting the appropriate accuracy specifications.

- Record the maximum load in Newtons within a 1% accuracy.

Test Results

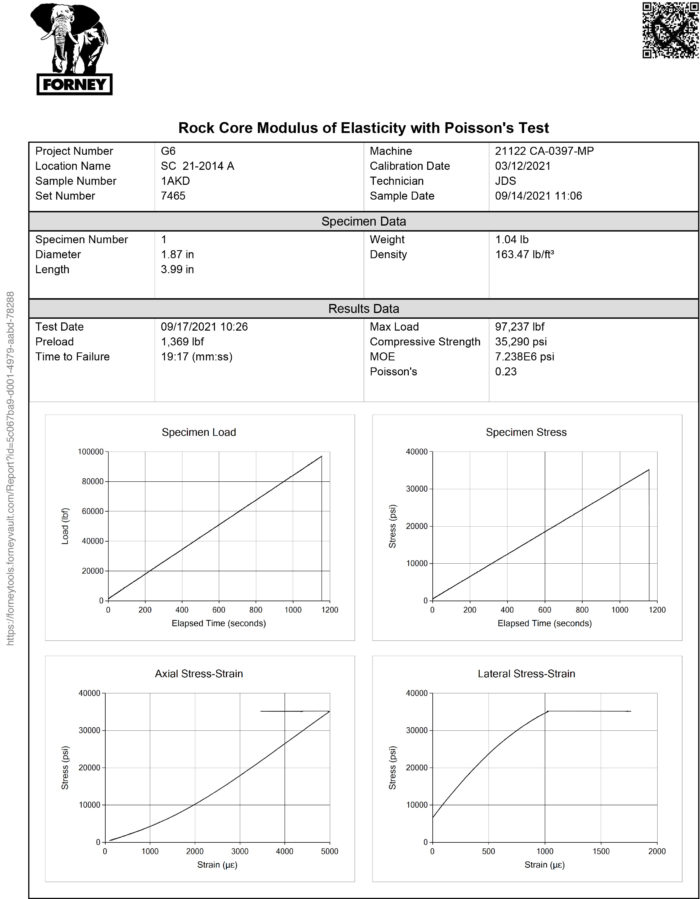

The test produces a stress-strain diagram that shows the results of the failure process and is used to complete calculations, including axial strain, diametric strain, compressive stress, MOE and Poisson’s Ratio.

With Forney’s 250 Series, you can immediately generate a full report of results (including the original XY graph) and export via the ForneyLink HMI. Test data is readily available for calculations and you don’t have to manually record any information. Testing intact rock core is a critical step in a construction process, so it’s paramount to protect the accuracy of results.

Conclusion

Intact rock core represents the very foundation of a structure. That’s why accurate testing is required to ensure the rock mass can withstand the weight of a structure.

ASTM D7012 outlines the proper procedure for testing the rock cores, and now you know what equipment to use for precise results. But before you conduct this test, be sure to reference the current ASTM standards.

Have questions about performing ASTM D7012? Need testing equipment? Contact us for help.