After going through the required training and earning the proper certifications, construction materials testing lab machine technicians have a hard job: long hours of detailed work with critical information on the line. Here are 3 ways CMT software can help make the job easier (and more valuable) for material machine users.

Between having the technical knowledge of various construction materials and test procedures and meeting the physical demands the job requires (standing for long periods of time, lifting heavy equipment or materials, etc.), being a construction materials testing machine technician can be a challenging job.

This was especially true when manual testing machines were the standard. Machine technicians would have to constantly monitor and manually adjust the valve to achieve specific rates – especially for standards that require precise control like cyclic testing.

Today, the headaches of manual testing machines are no more thanks to the new standard: automatic testing machines. No matter what type of machine you need – be it compression, flexural, or something universal or specialty – you can get it with automatic controls, providing better accuracy, consistency and repeatability to the testing process.

But there is more that can be done to make the testing job easier – benefiting both the machine technician and the testing organization as a whole. It’s called construction materials testing software: a machine-integrated platform that unifies the CMT workflow from the moment field data is captured in the system, to specimen curing and identification, to validation and testing, to sign-off and next steps. For machine users specifically, CMT software presents three helpful benefits.

3 Benefits of CMT Software for CMT Machine Users

#1. Faster & More Reliable Test Assurance

Even with an automatic machine, machine technicians have to manually select and verify the specimen they need to test. This process is prone to human error and takes time to complete. What if you could identify the specimen you need to test, automatically verify that all the parameters are correct, and get started with the test even faster?

With CMT software, you can.

This is thanks to the machine-integrated nature of the platform. The integration is two-way, which means CMT software can actually preload specimen data into the testing machine before the test (in addition to transferring results exactly where you need them after the test).

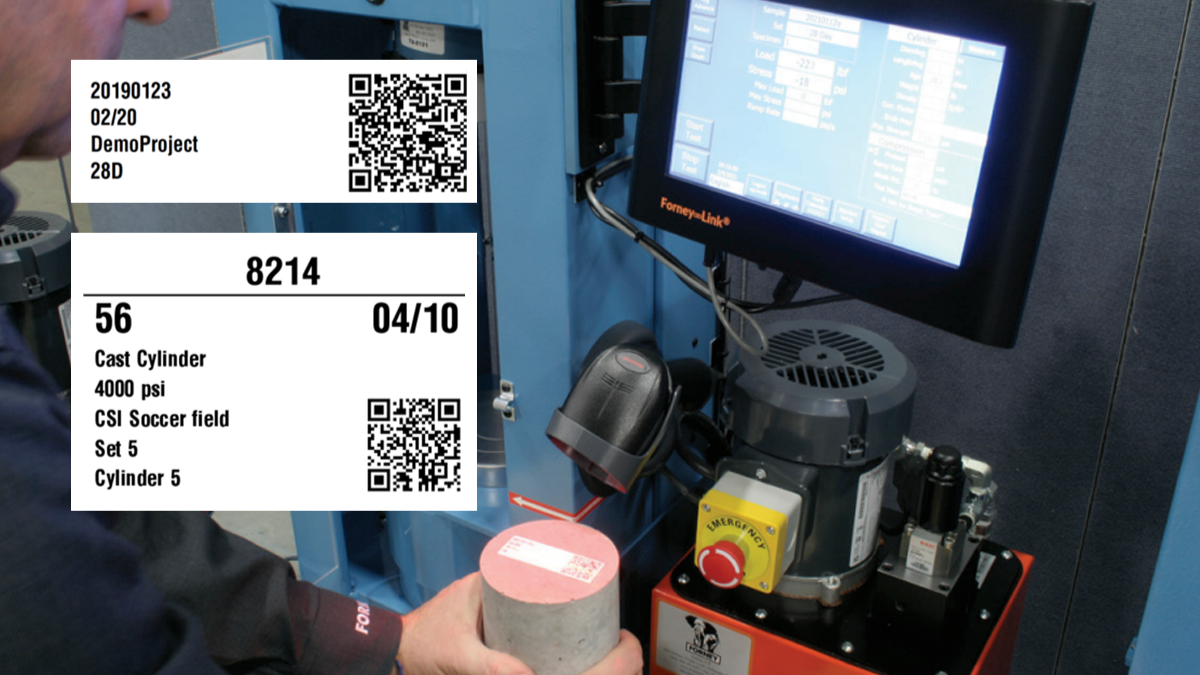

This process is made possible by creating a unique identifier associated with each specimen, which can be printed as a barcode on the specimen. So, when it’s time to test, the technician can scan the barcode and see all relevant information – like the sample date, size, type and expected strength – right away. The machine itself will validate the test based on these parameters, and it won’t allow a test to start without a manual override if, for example, the test date is incorrect. This ensures that the right specimen is tested on the right data and is always associated with the right sample and project.

Faster, automatic test assurance streamlines the machine technician’s workflow even more, ultimately making the job less stressful and more reliable.

#2. Ensure Quality & Compliance

In a similar vein, quality and compliance is a critical part of construction materials testing processes and data. At best, noncompliance can cost an organization hundreds of thousands of dollars. It can also lead to lost business and, at worst, deadly structural failures.

With CMT software, the process of quality and compliance is much more secure:

- Tests are validated with smart checks (see point #1).

- Test methods are transparent and verified to the required standard.

- Report generation is fully automated.

- Detailed, original X-Y graphs of stress vs. time are stored forever.

These benefits prove invaluable to testing organizations. If a project engineer questions the validity of results, the technician can leverage CMT software to see the full history of tests, including who tested the cylinder, what time, what the rate ramp was, and everything in between. Ryan Kauffman, the Concrete Lab Supervisor at Braun Intertec using CMT software in his lab, says it best: “When our project engineers ask us if we’re sure the results are right, I can honestly say they are 100% correct with absolute certainty.”

This level of certainty protects not only the organization as a whole but also the jobs of the people responsible for handling the test and data.

#3. Improve Productivity

In high-volume testing labs, productivity is everything. Every minute also counts in smaller volume labs. And the charge for the construction industry the past few years has been all about creating efficiencies and doing more work with fewer people.

How can already busy machine operators meet this demand for higher productivity?

CMT software is the answer. The automatic specimen verification helps technicians move faster with test setup and cleanup. See the difference below.

ForneyVault + VFD | Enhanced Productivity from ForneyVault on Vimeo.

Ryan’s lab followed a similar approach to the above: “We were always operating at 100-125%. Within 3 months of implementing ForneyVault, not only were we keeping up but we also were above the water. Now, we can spend more time on each individual sample quality, not doing the busy work.”

On the other end of the test, CMT software greatly reduces clerical and administrative tasks, like results transfer and report generation.

Conclusion

Being a CMT machine operator is not for the faint of heart. However, there are still things that can be done to lighten the load – and protect the liability of the individual and the organization. Technicians can take pride in knowing that their work helps ensure the safety and quality of construction projects, and CMT software ultimately allows that to be as true as possible.

Forney offers powerful automatic testing machines and CMT software that makes machine users’ jobs more effective. See how it all works by scheduling a demo.