Cold crushing strength and modulus of rupture determine the suitability of dried or fired refractory materials for use in high-temperature conditions. ASTM C133 provides the standard methods for measuring these properties.

Refractory construction is a unique application that requires materials that can withstand high temperatures. For example, furnaces, kilns, incinerators and reactors all require refractory materials.

Strong, durable refractory materials are essential to maintain the integrity of these high-temperature use cases. To ensure the quality and performance of these materials in service conditions, construction material testers need to measure cold crushing strength and modulus of rupture according to ASTM C133.

In this article, we cover the basics of ASTM C133:

- What ASTM C133 includes

- Recommended equipment for cold crushing strength

- Test procedure & results for cold crushing strength

- Recommended equipment for modulus of rupture

- Test procedures & results for modulus of rupture

What does ASTM C133 include?

ASTM C133 covers the steps for determining both cold crushing strength and modulus of rupture for bricks and other refractory shapes, insulating brick or shapes, and castable refractories.

- Bricks & shapes: pre-formed, solid pieces made from refractory materials that offer the most durability.

- Insulating bricks & shapes: lightweight, porous refractory materials that prioritize thermal insulation over durability.

- Castable refractories: unshaped, moldable mixtures of refractory materials that can be cast into place.

To evaluate the characteristics of these materials, ASTM C133 provides references for preparing specimens, required equipment, and the testing procedure for both cold crushing strength and modulus of rupture.

- Cold crushing strength: the maximum compressive load a refractory material can withstand at room temperature.

- Modulus of rupture: the measure of a refractory material’s strength when subjected to bending or flexural stress at room temperature.

ASTM C133 does not provide a measure of performance at elevated temperatures. Rather, the test methods determine the room temperature compressive strength (cold crushing strength) and flexural strength in three-point bending (MOR).

Here’s what you will need to perform these methods.

Recommended Equipment for Cold Crushing Strength

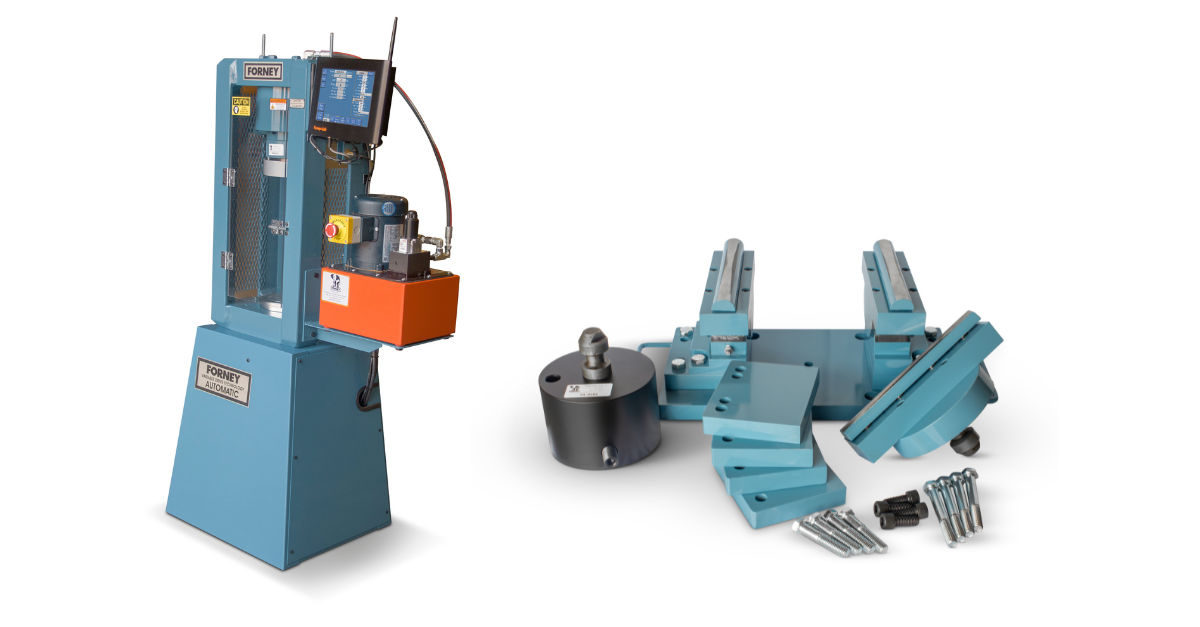

To test the cold crushing strength of refractory materials prepared according to ASTM C862 and ASTM C1054, you will need a compression testing machine that conforms to the requirements of ASTM E4.

A compression testing machine determines a material’s strength and deformation behavior under compressive (pressing) load.

Related Reading: Glossary of Construction Materials Testing Terms

ASTM C133 cites that a standard manual or automatic testing machine can be used. However, the control of the test procedure has very specific load, stress or displacement rate guidelines depending on the type of specimen and its measurements. For example:

Where possible, ASTM C133 prefers loading at a constant stress rate to constant strain rate.

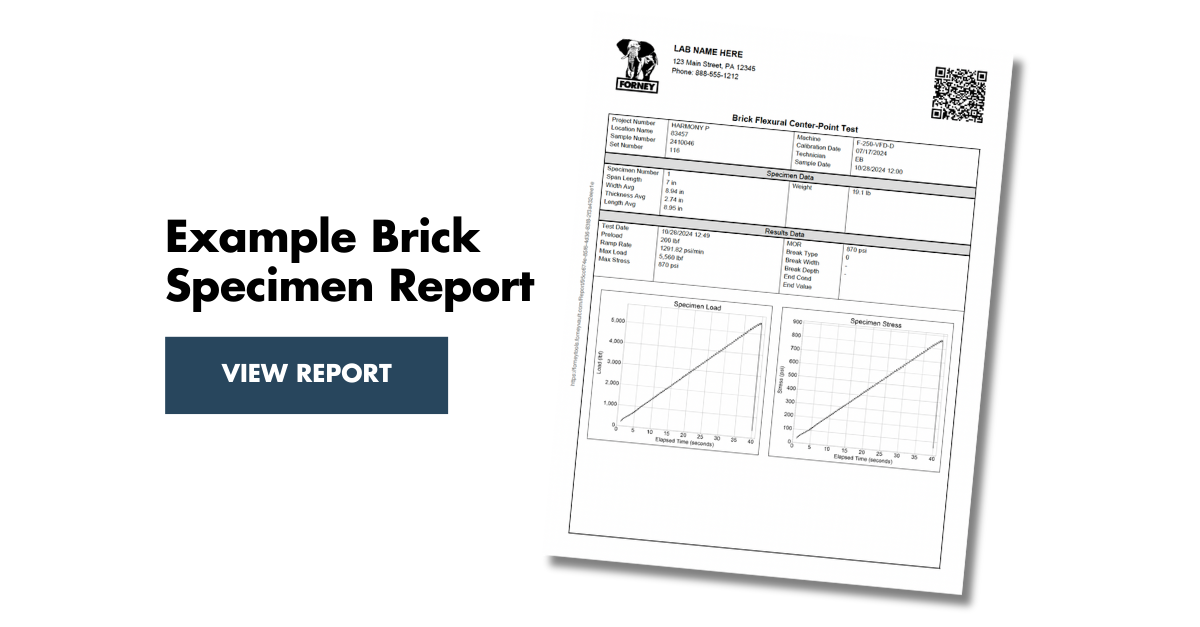

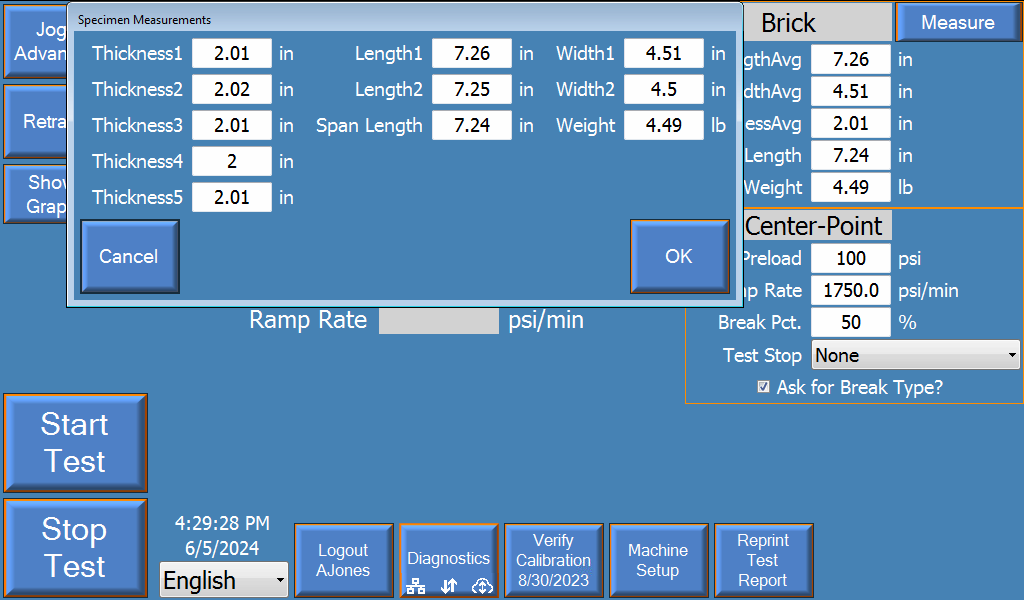

A Connected Machine – with automatic controls and integrated testing software – helps machine technicians with the challenges of ASTM C133. Thanks to the native two-way integration with material testing software, a Connected machine provides pre-test “Smart Checks” to validate test parameters and measurements and run automatic preload calculations according to ASTM standards. During the test, the machine automatically controls the rate – whether load, stress or displacement. After the test, calculations and values transfer to your LIMS or other software of choice.

This allows technicians to get more done faster while ensuring the highest level of quality for testing the cold crushing strength of refractory materials.

To prepare for the test, you will also need a spherical bearing block, which is an apparatus that ensures the load is evenly distributed for better results.

The spherical bearing block’s plane surface area should be equal to or greater than the cross section of the test specimen.

Depending on your test specimen, you may need a 0.25 inch cellulose fiber wall board as a bedding material in between the bearing block and specimen.

With this equipment, you’re ready to conduct a cold crushing strength test according to ASTM C133.

Cold Crushing Strength Test Procedure & Results

- Place the test specimen in between the testing machine platens. For brick and shapes and regular and high-strength castables, place the specimen in between bedding material. For insulating brick and shapes and insulating castables, apply the load directly.

- Position the test specimen so the center of the bearing block aligns with the vertical axis of the specimen.

- Position the spherical bearing block by hand under a small initial load.

- Apply a consistent load until failure.

- Record the maximum applied load.

- Repeat the procedure for at least five specimens.

- Calculate cold crushing strength by dividing the total maximum load by the average of the specimen’s top and bottom areas.

In addition to calculating this result, ASTM C133 requires testers to report details about the specimen:

- Designation of the materials tested

- Specimen configuration

- Pretreatment information

- Number of specimens contained in a sample

- Individual specimen dimensions

- Maximum applied load

- Cold crushing strength for each specimen

- Mean cold crushing strength and the standard deviation for each sample

With a Connected machine, this information can be automatically calculated and compiled into the appropriate reports, saving you time and ensuring high quality results.

ASTM C133 continues by breaking down the recommended equipment and test procedure for calculating modulus of rupture.

Recommended Equipment for Modulus of Rupture

Like the cold crushing strength test, the modulus of rupture measurement uses a compression testing machine and flexural bearing surfaces.

In addition to following the required dimensions specified in ASTM C133, all bearing surfaces must be straight and at least as long as the specimen’s width. Also, the supporting members for the lower bearing plane should align with the underside of the specimen in case the brick has a longitudinal twist.

Here’s how the test works.

Modulus of Rupture Test Procedure & Results

- Place the test specimen on the bearing cylinders with the span specified in ASTM C133, depending on the type and dimensions of your specimen.

- Apply the load at mid-span in flexure according to the specified loading rates.

- Record the specimen configuration and dimensions and maximum load.

- Repeat the procedure for at least five specimens.

- Calculate Modulus of Rupture with the following formula: MOR = 3PL/2bd2

Here’s what each value of the formula represents:

- P = maximum applied at rupture

- L = span between supports

- b = breadth or width of specimen

- d = depth of specimen

In addition to calculating the modulus of rupture, ASTM C133 also requires testers to report details about the specimen:

- Designation of the materials tested

- Specimen configuration

- Pretreatment information

- Number of specimens contained in a sample

- Individual specimen dimensions

- Maximum applied load

- Location of the fracture plane

- Calculated modulus of rupture for each specimen

- Mean modulus of rupture and the standard deviation for each sample

Just like cold crushing concrete, the modulus of rupture measurements and associated reporting can be more efficient, accurate and transparent with the help of a Connected testing machine and integrated material testing software.

Conclusion

ASTM C133 ensures material testers follow standard test methods for cold crushing strength and modulus of rupture of refractories. While this simple guide includes everything you need to get started, please review the current ASTM standard for the most up-to-date regulations.

Forney has the machines, accessories, and software necessary for ASTM C133. Shop the Forney store today or find your machine.