SPECIALTY TESTING MACHINES

CUSTOM MACHINES FOR SPECIAL APPLICATIONS

Work with Forney’s team of experts to design a machine that meets your unique needs while maintaining ASTM and ACI specifications.

FORNEY SPECIALTY TESTING MACHINES

Forney engineers can adapt machines to meet your specific needs. We work with professionals in civil engineering, DOTs, universities, manufacturing sectors and government agencies to deliver creative yet practical and cost-effective solutions to complex problems.

- Manual, Automatic or Connected Control

- Backed by the best technical support team in the industry

- Recent innovations include concrete railroad tie testers, proppant testers for hydraulic fracturing sand, tile testers and more

FORNEY INNOVATIONS

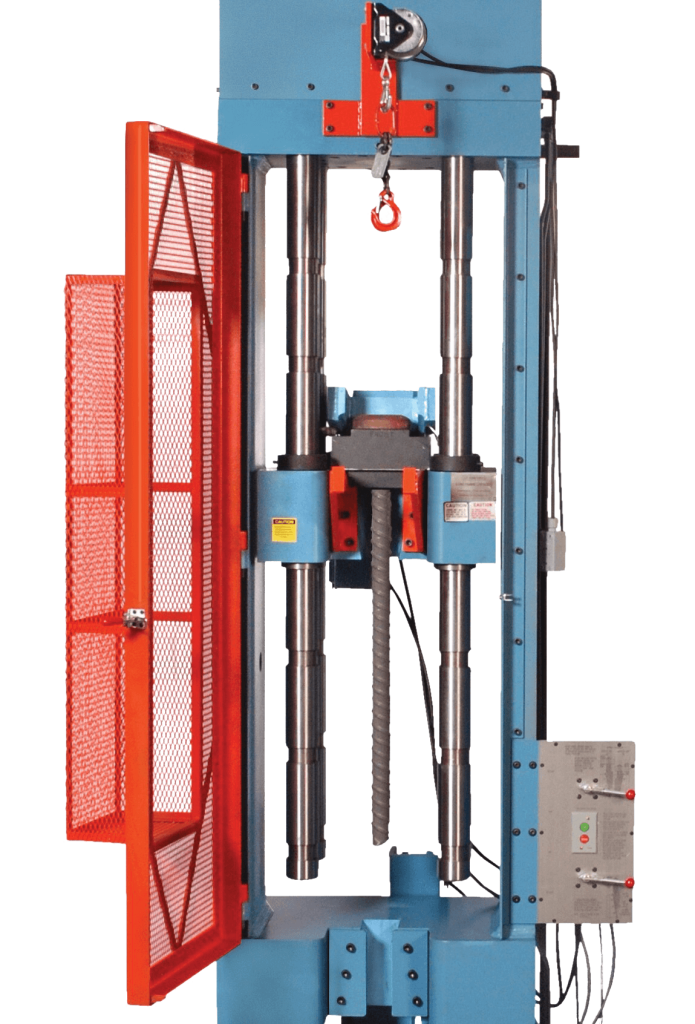

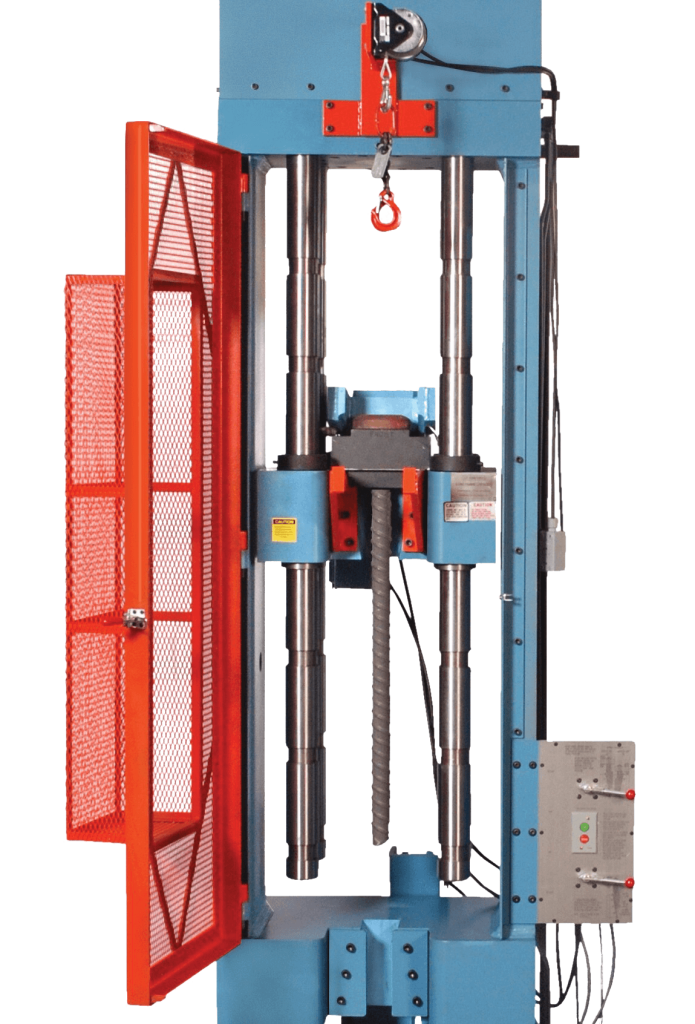

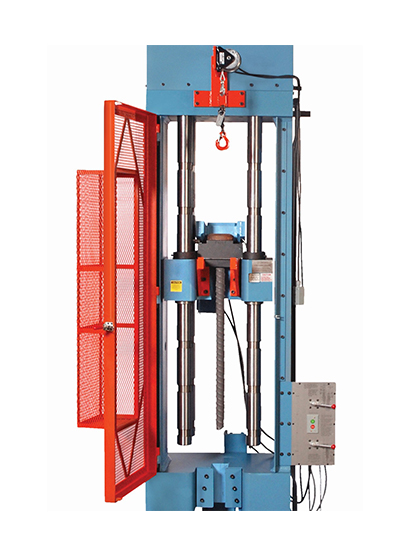

REBAR WITH T-CAP TESTER

This custom-designed machine was adapted from a Forney Universal Tester with Extended Frame in order to test rebar with T-Caps in tension. Working with the customer, the Forney Engineering Team knew that maintaining frame rigidity would be extremely important. Taking a normal frame and doubling its overall height requires more than simply stretching the drawings—a myriad of calculations went into the creation of this machine. You probably didn’t know that changing the length of a machine changes the required testing speed! Our engineers know the ins and outs of machine building to meet specifications.

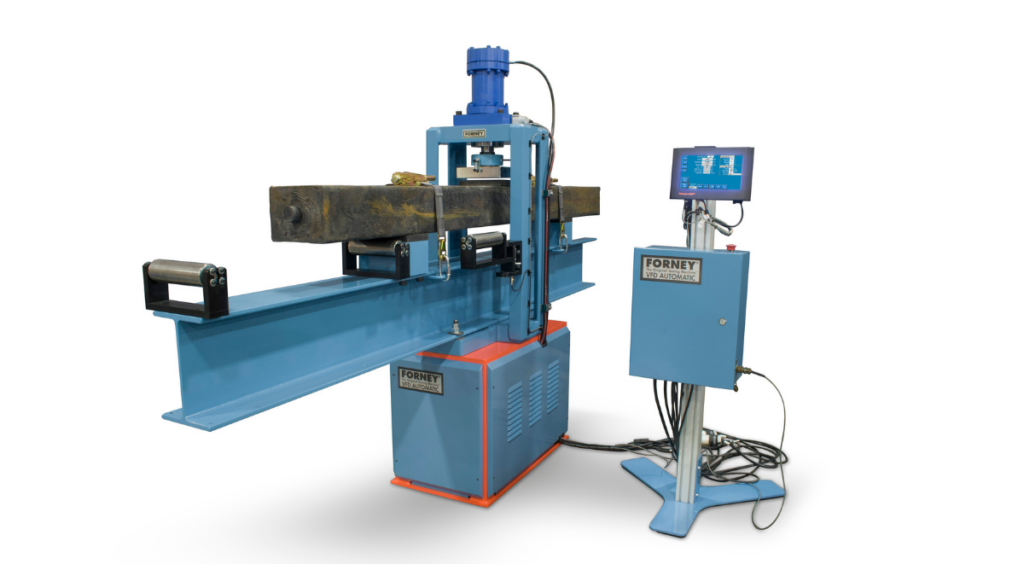

LT-8152 COMPRESSION TESTER

Designed and built by Forney, the LT-8150 Series Compression Testing Machines are specifically designed for testing a variety of materials in compression and flexure – including cementitious and metallic materials like briquettes, cubes, cylinders, as well as other non-cementitious and non-metallic materials. Due to the high force capabilities of these machines – up to 1.5M lbf, they are particularly well suited to tests on larger specimens, higher strength specimens, or a combination of both. LT-8150 Series Compression Testing Machines can be equipped to measure Force, Displacement, Velocity and Strain.

PIPE TESTER

Forney’s Pipe Tester kit consists of a steel weatherproof cabinet that houses the digital indicator, pump, hydraulic ram and hoses, and mounting cylinders. In combination with a Pipe Tester frame (either built by Forney or supplied by the customer), the kit becomes a complete Pipe Tester system.

ENGINEERED COMPOSITE TIE TESTING

To properly test engineered composite ties, a number of lab tests are required. Forney’s LA-300-VFD Railroad Tie Tester can streamline testing for engineered composite ties using standardized testing protocols. A cost-effective machine, the LA-300-VFD can be leveraged in the QA role of a production facility to ensure quality manufacturing of composite rail ties.

PORE FLUID EXPRESSION TESTER

This custom machine is designed for the expression of pore solution from hardened portland cement pastes and mortar. The apparatus that is installed in the machine is designed to generate the 80,000 psi internal pressure needed to express pore fluid from the sample. Because of the high stress of the apparatus, the machine included Lexan doors at double the normal thickness, heavy-duty door latches, and door switches that prevent running the machine without closing the doors. The machine was also custom programmed to run the required cyclic test protocol.

Connect Your Machine Interface with Smart CMT Software

- Pre-test “Smart Checks” validate test parameters

- Test faster with automatic preload calculations

- Two-way integration with CMT software

- Positive Specimen identification with Bar Code Scanning

- Automate the management of test specimens

- SMS Alerts / Notifications based on test performance/results

HAVE A SPECIAL TESTING CHALLENGE? LET US HELP.

Get the Latest from Forney In your inbox

Enter your email below to subscribe for updated news on Forney’s construction materials testing solutions.