Due to their larger size, segmental concrete paving slabs for commercial building projects do not fall under ASTM C936. That’s why paving slab manufacturers, material suppliers, testing labs and other experts joined forces to develop ASTM C1782.

This post covers the ASTM C1782 specification, as well as Annex A8 of ASTM C140 which specifies appropriate testing equipment and calculations to ensure the design, performance and safety of your segmental concrete paving slabs.

To see a test of segmental concrete paving slabs in action, check out this video of our FW-100-VFD-C machine automatically running the test. To learn how to perform it yourself—keep reading.

What are Segmental Concrete Paving Slabs?

Segmental concrete paving slabs are concrete units manufactured for the construction of pedestrian and roof applications for municipal and commercial projects.

Functional, durable and aesthetically appealing for architects, civil engineers and landscape architects, segmental concrete paving slabs have become a common construction material for projects where close dimensional tolerances for thickness, length and width are not required.

Like any construction material, segmental concrete paving slab’s properties must be properly verified. Poorly designed or improperly tested paving slabs can, for example, leave a roof with cracks, inviting leaks and leading to structural issues.

Getting Started With ASTM C1782

ASTM International, globally recognized for developing and delivering testing standards for construction materials, issued ASTM C1782 in 2016.

Under this specification, any concrete paving slab ranging from 12×12 inches to 48×48 inches must meet minimum requirements for flexural strength, dimensional tolerances and freeze-thaw durability.

ASTM C1782 also offers a manufacturing standard for concrete paving slabs made from dry-cast, wet-cast and hydraulically pressed processes. The concrete paving slabs should include aggregates that are lightweight, normal weight or both.

Segmental concrete paving slabs are larger in size, so they didn’t fit under the existing ASTM standard for interlocking concrete paving units (C936). As a result, there was no baseline production standard, which led to issues with pavement design and integrity. ASTM C1782 solved this problem.

The introduction of this standard unlocked three opportunities for the industry:

- Benefit Architects and Engineers when writing construction specifications

- Allow manufacturers to promote products that meet or exceed requirements

- Give concrete testing labs the opportunity to provide an additional service

All of these objectives can be met through proper materials testing. Here’s what you will need to get started.

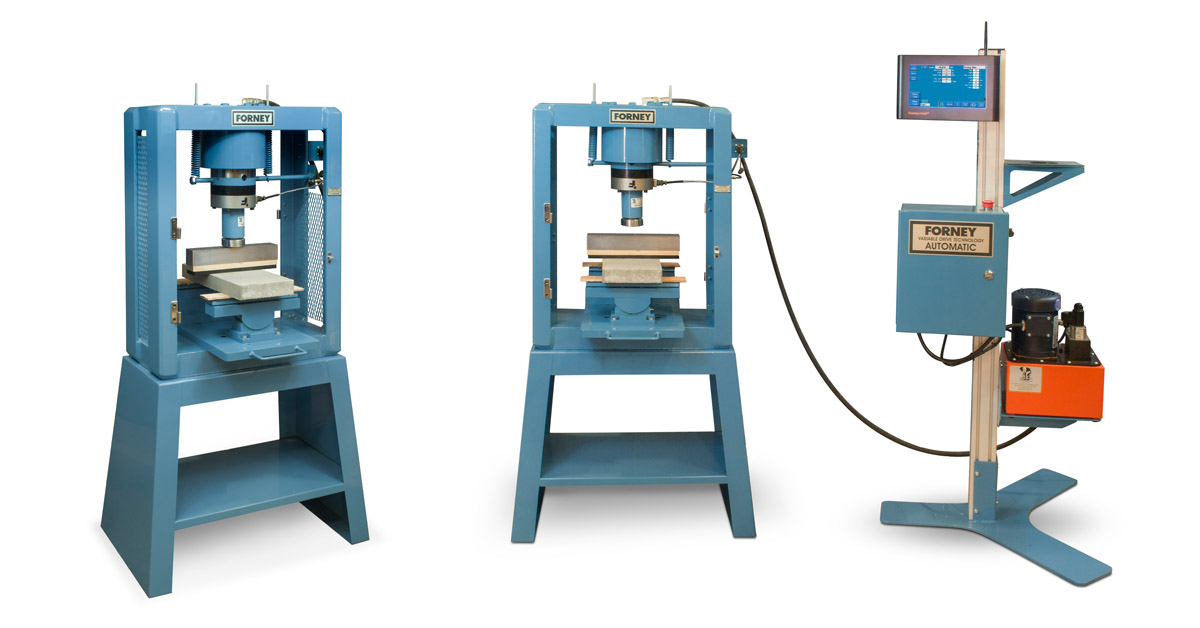

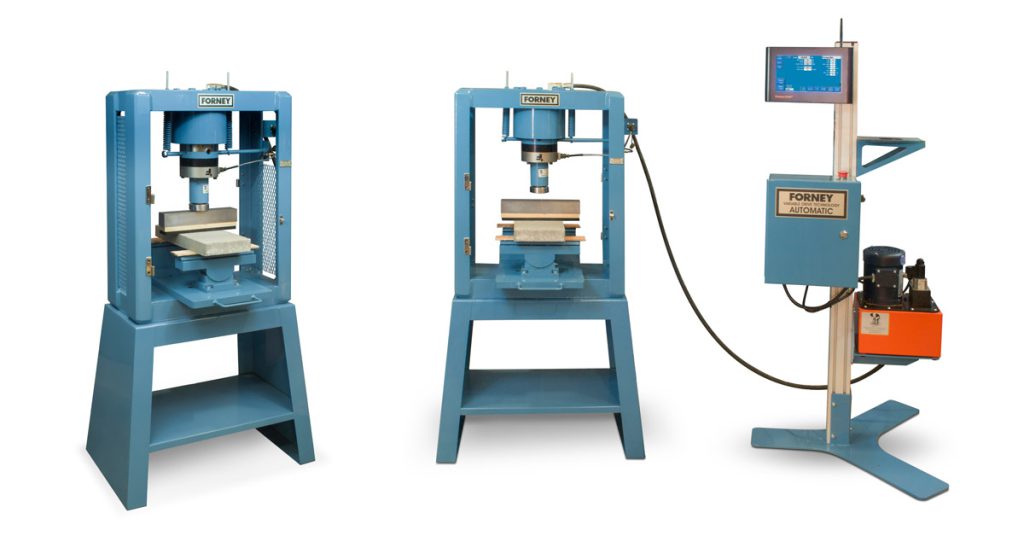

Recommended Equipment for Segmental Concrete Paving Slab Testing

To perform tests for the flexural strength requirements of ASTM C1782, you will need an automatic compression testing machine/system fitted for flexural tests.

The test is to be conducted according to procedures detailed in ASTM C140 Annex A8, and the Modulus of Rupture in particular as described in C140 Annex A8.4. This type of test is meant to determine characteristics of a product, as opposed to a material. The Paving Slab can be modified to adapt it to the available testing machine. If that’s necessary, the modifications must be done in a manner to still measure the desired characteristics.

Additional tests to determine material performance may be required by the specifier. Mix design and other characteristics can be determined according to ASTM C39 and other tests.

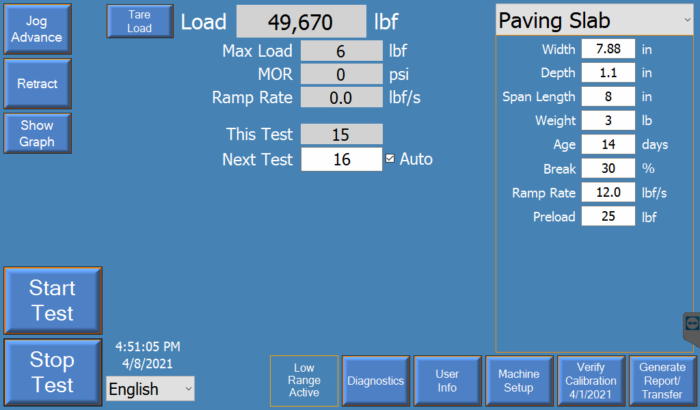

Forney supplies an FW-100-VFD-C designed to perform ASTM C140 on concrete paving slabs. With automatic control systems, the FW-100 Series allows you to consistently and accurately test the concrete units at the correctly controlled loading rate. This test in particular requires a very slow rate of load and is difficult if not impossible to control via traditional manual hydraulic control systems.

ASTM C1782 Test Control & Procedure

Test Control

Rate of load must be controlled for the duration of the test. With a manual testing machine, this can be difficult or near impossible because it requires your operator to keep a consistent rate of load for the entire test. The low loading rate is difficult to achieve in the first place, and even more difficult to maintain as the deformation of the specimen changes throughout the test. Even the best operator is going to have variations—which can lead to imprecise results.

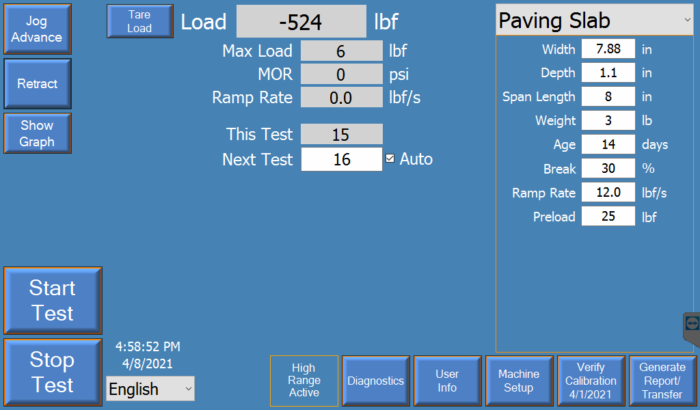

Luckily, Forney’s VFD control software adjusts control parameters throughout the test to ensure the test runs with no problems under all conditions.

With this control parameter in mind, here’s how to run the test required by ASTM C1782 and according to ASTM C140 Annex A8.

Test Procedure

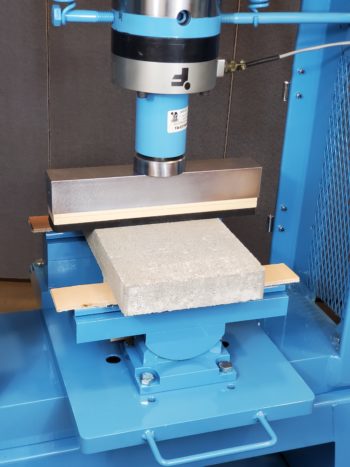

- Prepare and position the specimen carefully and orient it according to the requirements of ASTM C140 Annex A8.

- Ensure the specimens are free of visible moisture or dampness.

- Load the specimen on the bearing supports.

- Properly tare the machine.

- Run the test at the specified rates.

- Record and report the maximum compressive load.

Test Results

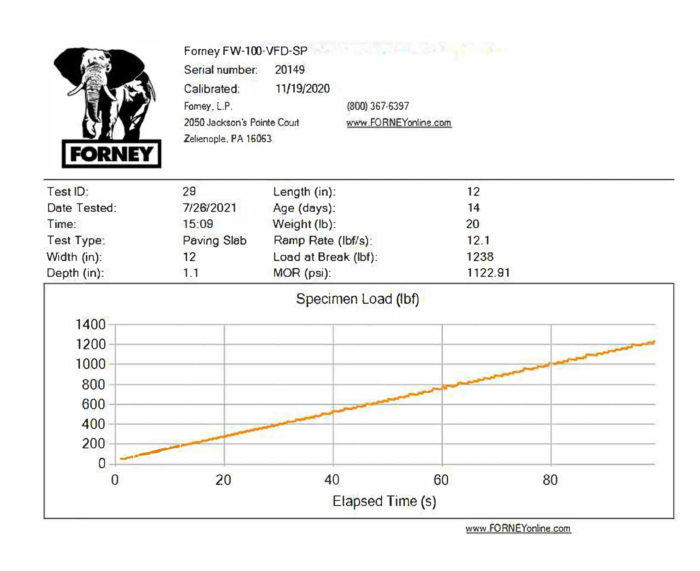

After the test, you can immediately generate a full report of results. Test data is readily available right from the ForneyLink HMI, so you don’t have to manually record any information. Simply save, print and share.

Conclusion

Segmental concrete paving slabs are valuable materials for paving and roofing projects, but they require accurate testing to ensure they meet design specifications and are safe for construction.

ASTM C1782 takes the guesswork out of whether concrete paving slabs are fit for building, and now you know which equipment to choose to ensure you get precise results. But before you conduct this test, remember to reference the current ASTM standards.

Have questions about performing tests required by ASTM C1782? Looking for equipment or software? Contact us for all your needs.