Typical concrete testing begins with fresh, uncured concrete measurements, like slump and air entrainment. It concludes with the measurement of compressive strength by pushing on a concrete specimen until it breaks. But it’s also important to see how concrete responds to other directional forces. That’s where modulus of elasticity (MOE) and Poisson’s ratio come in.

In this post, we walk through the ASTM C469 test method: the standard test method for static modulus of elasticity and Poisson’s ratio of concrete in compression. We’ll also cover:

- Why MOE and Poisson’s ratio are important for concrete testing

- Recommended equipment

- How to calculate results

Getting Started with ASTM C469

ASTM International updated the testing standard for MOE and Poisson’s ratio of concrete in compression in 2022. Let’s review what MOE and Poisson’s ratio mean and why they’re important.

Modulus of Elasticity of concrete is a measure of concrete’s ability to resist deformation when subjected to load. From a layman’s point of view, concrete is impregnable and rugged. Wouldn’t an infinitely resistant concrete be the best concrete?

Not necessarily. In nearly all types of materials, a certain flexibility or elasticity (hence the name) is important to allow structures to flex in response to live loads. Whether it’s a truck driving over a bridge, a wind load on an apartment building, or an earthquake shaking a foundation, structures must flex (or deflect) and return to their original state to avoid cracking and premature failure. Some of this flexibility is determined by the component geometry, but it’s also determined by the material property – the modulus of elasticity (also known as Elastic Modulus or Young’s modulus). MOE then, measures how much the concrete stretches or compresses in response to a given force and then returns to its original state, thereby demonstrating both its stiffness and elasticity.

There is a deformation point for all materials, including concrete, beyond which no recovery is possible. That’s the Elastic Limit, and that value is determined by the MOE test. Structures stressed beyond their materials’ Elastic Limit will not return to their original state. It’s a critical metric for designers and affects many factors – from performance to cost.

In some cases, it’s important to have as slender a concrete component as possible to reduce weight or surface area. In that case, a high-performance, high modulus concrete is in order.

Prestressed components are vulnerable to loss of prestress tension if the concrete can “give” too much for the applied prestress loads. This is also a good case for high modulus concrete. These products involve a sophisticated blend of sizes and types of aggregates along with cement pastes, which can cost considerably more than conventional concrete. So, picking the right product for the job is critical, and verifying its performance is essential.

The Elastic Modulus measures load versus deformation in an axial fashion (whether it’s tension or compression). Poisson’s ratio measures the load versus deformation performance perpendicular to the direction of the load.

Most materials, including concrete, tend to “swell” or increase in diameter while being compressed. Poisson’s ratio is a measure of that swell in relation to the compressive stress. It’s a ratio because it compares the axial to the perpendicular load/deformation values.

Together, these two values help construction engineers:

- Determine the size of structural members.

- Determine the quantity of reinforcements.

- Compute the stress for observed strains.

Here’s what you’ll need to perform ASTM C469.

Recommended Equipment for MOE & Poisson’s Ratio Concrete Testing

Three pieces of equipment are needed:

- Compression testing machine

- Compressometer

- Extensometer (for Poisson’s ratio)

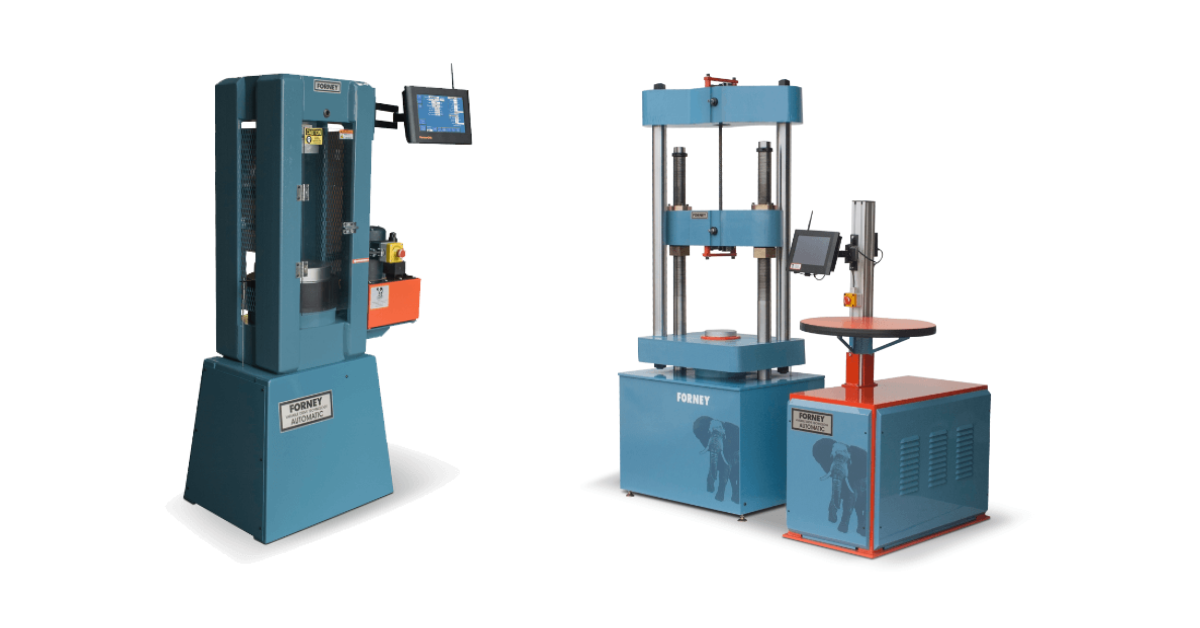

Compressive and universal testing machines can be equipped to properly conduct MOE and Poisson’s ratio for concrete.

ASTM C469 requires a machine whose rate of load can be fully controlled in both an increasing as well as decreasing direction. Most manual and some automatic machines, compressive or universal, are not so equipped. We’ll discuss this more when we talk about test control below.

Next, you will need a compressometer for MOE, or a compressometer/extensometer for MOE and Poisson’s Ratio.

A compressometer is a device used to determine the strain of a specimen while measuring compressive strength. For concrete, the device typically has two rings that mount to the cylinder, control rods and a digital indicator for reading. As the test runs and the compressive load is applied, a stress strain curve is generated (either manually or via an automatic data logger), which is then used to determine MOE.

An extensometer is typically a third ring between the two compressometer rings, and it measures the lateral strain to generate a stress strain curve for calculating Poisson’s ratio.

Here’s how the process works.

ASTM C469 Test Control & Procedure

Test Control

To achieve compliance, ASTM C469 requires the loading and unloading rate to remain steady at 35 psi/s the entire course of the test. The standard also requires you to load your specimen to 40% of its estimated strength, instead of loading it until the point of failure.

This level of precision makes manual machines unsuitable for compliance. Plus, you must take readings continuously without any delay throughout the test in order to generate an accurate stress strain curve over time. An automatic testing machine solves both of these problems by automatically holding the load rate and calculating the stress strain curve.

With these control parameters in mind, here’s how the test works when attempted on manual control machines.

Test Procedure

- Determine the compressive strength of another concrete specimen of the same sample by following ASTM C39.

- Attach the compressometer/extensometer to another specimen of the same sample. Apply the load at a constant rate (typically 35 psi/s) until it reaches 40% of the load from step #1. Return the load to zero at the same rate.

- ASTM C469 recommends completing at least two more loadings to ensure repeatability.

- During loading, record:

- Applied load to calculate stress

- Longitudinal displacement

- Transverse displacement (if calculating Poisson’s ratio)

- Calculate specimen axial stress from the applied load values captured above.

- Calculate longitudinal strain from the longitudinal displacement values captured above.

- Calculate transverse strain from the transverse displacement values captured above (if calculating Poisson’s ratio).

- Calculate MOE and Poisson’s ratio from the stress and strain values of the second two loadings and take the average of the results if repeatable. (Do not include the first loading, which is mainly used to seat the strain measuring equipment.)

Calculating Results

During the test on a manual machine, a technician must manipulate the controls to achieve the 35 psi/s specification and, at the same time, record readings at various intervals to create the stress strain (or load-deflection) curve. That’s a tall order!

The slope of this curve provides the MOE of concrete. For Poisson’s ratio, the technician must capture three sets of values. The calculation is the negative of the ratio of transverse strain to longitudinal strain.

This is a complex, time-consuming process that relies on ultimate precision, expert calculations, and no distractions. Typically, it takes at least two people to run the test and capture MOE values, or three people for Poisson’s ratio. However, there’s a better way.

Automatic Calculations

An automatic testing machine combined with an integrated construction materials testing platform will help you get the results you need right away, without needing multiple people to run the test or having to conduct tedious calculations. At test completion, the MOE and Poisson’s Ratio values are automatically calculated and displayed.

The Forney VFD machine can be equipped to manage the rate specifications automatically – both up and down load. Plus, it captures all data, including key data points for the stress-strain graph.

That data then flows seamlessly into ForneyVault, a secure cloud-based CMT platform. The MOE and Poisson’s ratio values are immediately available at the end of the test, and ForneyVault enables you to immediately generate a full report of the test, including all calculations required by C469.

Conclusion

Testing for static MOE and Poisson’s ratio is another essential part of concrete testing to provide a well-rounded, complete view of a material’s durability. Before performing ASTM C469, please be sure to reference the current ASTM standard.

Questions about performing ASTM C469? Need equipment or software? Contact us to discuss your needs.