Splitting tensile strength is an important performance metric that assesses the durability of concrete. ASTM C496 covers the standard method for determining the splitting tensile strength of cylindrical concrete.

Concrete strength tests use various specimen types to measure a specimen’s resilience to specific forces. Test cylinders are commonly used because they evenly distribute applied forces and closely resemble real-life concrete applications.

A concrete test cylinder is a cylindrical specimen that can be made in two ways:

- Pouring fresh concrete into a mold on the job site, allowing it to set and cure.

- Drilling cores from existing structures.

SHOP NOW: Concrete Coring Supplies

ASTM C496 is the standard used to determine the splitting tensile strength of these concrete test cylinders. In this article, we cover the basics, including:

- The importance of ASTM C496

- Recommended equipment for ASTM C496

- Test procedure & results

The Importance of ASTM C496

Splitting tensile strength is the ability of a material to withstand tensile stresses applied perpendicular to its surface, causing it to split or fracture.

In a splitting tensile strength test, also known as indirect or Brazilian tensile testing, the cylinder is placed on two parallel platens and a compressive force is applied perpendicular to the axis of the cylinder until it fractures. This results in a tensile stress being induced perpendicular to the direction of loading, leading to the specimen breaking along its diameter.

Splitting tensile strength is crucial in the design of structural, lightweight concrete applications, such as beams, columns, slabs, or panels. Engineers use splitting tensile strength to evaluate the concrete’s ability to withstand shear forces and determine the development length of reinforcement, which is especially important in structure design.

To conduct ASTM C496, you will need the concrete testing equipment detailed below.

Recommended Equipment for ASTM C496

- Testing machine – the testing machine must conform to the test method requirements of ASTM C39/C39M.

Compression testing machines are used to determine a material’s behavior under applied loads. A cylindrical concrete specimen is placed horizontally between two loading platens, one platen fixed while the other applies a compressive force perpendicular to the cylindrical axis of the specimen.

A universal testing machine is designed for a wide range of testing applications. Technicians can use these machines to measure and control various factors such as force, pressure, stress, strain, and low-range force across multiple axes and vector types.

Either a compression machine or specified universal testing machine may be used to test splitting tensile strength.

- Supplementary Bearing Bar or Plate – the bar or plate evenly distributes forces to a specimen during load. This item is used when the diameter or largest dimension of the upper bearing face or lower bearing block is smaller than the length of the test cylinder.

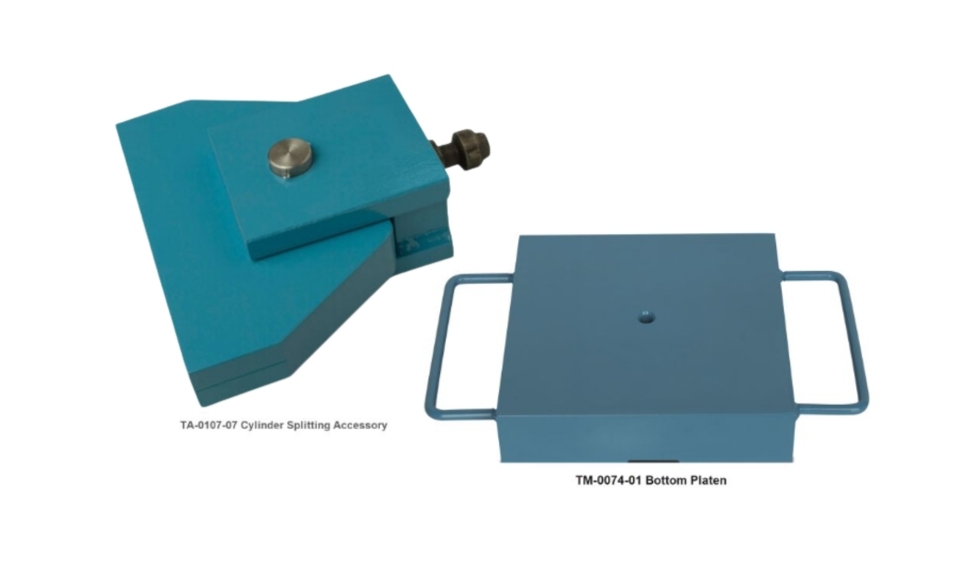

A tensile cylinder splitting set is affixed to the top platen for uniform force application during load:

This plate set ensures accurate and reliable tensile splitting, as it stabilizes the specimen and protects testing equipment from potential projectile damage.

- Bearing Strips – bearing strips are placed between the specimen and both the upper and lower bearing blocks of the testing machine. These strips create friction that securely grip the concrete cylinder, preventing its movement during the test sequence.

Related Reading | Simple Guide to ASTM C39: How to Test Concrete Cylinder Compressive Strength

With all the above concrete testing equipment, here’s how to follow the ASTM C496 test procedure and calculate results.

ASTM C496 Test Procedure & Results

Test Procedure

- Prepare test specimens to meet specific size, molding, and curing requirements. The drilled cores, if used, must also conform to size and moisture-conditioning requirements.

- Mark each specimen with a diametral line to ensure they are on the same axial plane.

- Take measurements of the test specimen’s diameter multiple times, averaging the results.

- Position plywood strips in the middle of the lower bearing block. Align the specimen on the strips so its marked ends are vertical and centered. Then, put another plywood strip lengthwise on the cylinder, aligning it with the previously marked diametral line.

- Align and center the jig so that the supplementary bearing bar and center of the specimen are directly beneath the spherical bearing block’s thrust.

- Apply splitting tensile stress until failure. Record the maximum load shown by the testing machine at failure, also documenting the type of failure and the concrete’s appearance.

Results & Reporting

To calculate splitting tensile strength:

- Multiply the maximum applied load by two

- Divide the result by the area of the cylinder

The factor of 2 in the numerator comes from the fact that the load is applied to the specimen through two diametrical points.

In addition to calculating this result, ASTM C496 requires testers to report details about the specimen:

- Identification number

- Diameter and length, mm

- Maximum load, N

- Splitting tensile strength calculated to the nearest 0.05 MPa

- Estimated proportion of coarse aggregate fractured during the test

- Age of specimen

- Curing history

- Defects in specimen

- Type of fracture

- Type of specimen

To achieve the most accurate results and comply with ASTM C496’s reporting requirements, machine technicians can use a Connected CMT Machine.

Related Reading | 5 CMT Machine Problems a Connected Machine Solves

This type of machine has a two-way integration with CMT software, exchanging data both before and after strength testing. Prior to testing, connected machines preload sample and specimen data to validate test parameters. After testing, the machine runs calculations and transfers values to your software of choice. This allows technicians to get more done faster while complying to the standard.

Conclusion

ASTM C496 ensures construction materials testing labs are following a uniform splitting tensile strength test protocol. While this simple guide includes everything you need to get started, please review the current ASTM standard for the most up-to-date regulations.

Forney has the compression machines, related accessories, and software for ASTM C496. Shop the Forney store today or find your machine.