New machine purchases are almost exclusively automatic, bringing unparalleled levels of accuracy and productivity to construction materials testing labs. However, these benefits may not be fully realized with just the machines themselves. Here’s why.

If your construction materials testing lab doesn’t have an automatic machine already, it’s only a matter of time before you do by upgrading or replacing your manual. This is because automatic materials testing machines provide overall better functionality and real-world performance compared to manual machines. They represent the new standard in CMT, for many reasons:

- Reduces variability with automatic preload and rate control.

- Allows busy machine operators to let tests run on autopilot (without impacting the accuracy and reliability of test results).

- Runs tests at the higher end of test speed tolerance, so more tests can be completed in a shorter time span.

- Uses energy-efficient hydraulic systems that eliminate excess oil flow, so machines run cooler and last longer.

Automatic materials testing machines are incredible innovations that make processes and products better. But when kept in a silo, there are still 3 things that can go wrong.

3 Reasons Why You Need More Than Just an Automatic Materials Testing Machine

#1. SPECIMENS CAN STILL BE MISIDENTIFIED

The machine does a great job streamlining the test itself. But this relies on accurately identifying the right specimen to test in the first place.

The reality is, handwritten labels on cylinders are still widely used – and widely susceptible to human error. Handwritten labels create a non-zero potential of misreading or misidentifying specimens. Every person in the chain handling the specimen must be able to read the first person’s handwriting or interpret any smudges that happen along the way.

Other meaningful data – like specimen dimensions, weight, density, break type and more – can be mistranslated during the test setup process, driving even more variability and errors into the results.

#2. TEST RESULTS CAN STILL BE MISHANDLED

Gone are the days of handwriting results on a clipboard to key into another system later. Most automatic testing machines offer some version of machine storage, printable reports, and result transfer capabilities.

However, even if handwriting isn’t involved, very often these reports still need to be retyped somewhere else, or otherwise manipulated at another step. This, of course, introduces opportunities for bias and errors, and more time in the process.

#3. THE MACHINE IS STILL ISOLATED FROM OTHER STEPS

Ultimately, an automatic machine is great at what it’s designed to do: automate construction materials testing. However, there are many steps before and after the test that machines can’t automate.

For example, fresh concrete data is captured in the field before the technician casts cylinders and sends them back to the lab for curing. This data includes important context at the sample level for each test specimen and informs future steps of the workflow. However, at the lab testing machine, the machine is isolated from this context. It’s up to the operator to provide the context and test parameters – a step that is vulnerable to mistakes.

Even with export functionality, automatic machines are generally isolated from other systems, like a Laboratory Information Management System (LIMS), quality control system or homegrown database. Results inevitably have to be retyped into these systems. Also, project engineers rely on manual communication to alert stakeholders when a report is ready for the review process. The entire report approval process can involve additional inefficient, untracked tasks such as emailing, moving files between shared folders or even delivering printed documents.

These untracked tasks and manual efforts cause “data to go dark,” in which you can’t see or verify where that data has been and how it has moved or changed. Untraceable data also leads to duplicated efforts, which wastes time and resources.

Unfortunately, the above three problems diminish the amazing benefits automatic testing machines have to offer. This is because an automatic machine does not guarantee a truly automatic workflow. There are still certain points in the process in which human hands have to intervene, introducing bias or errors into the process.

Luckily, it doesn’t have to be like this. Enter: Connected Construction.

How to Achieve Connected Construction

An automatic materials testing machine paired with other technology and software solutions represent a semi-automatic testing environment. However, truly automated testing means connecting all the dots – and removing those gaps where “data goes dark.”

To achieve this, you need a machine-integrated construction materials testing platform. This solution unites data flows across the entire construction ecosystem, from the material plant to the field to the project owner, and every step in between. (Check out the video below to see what this looks like.)

Importantly, this is much more than an integration that transfers results from the machine to software. It refers to a two-way integration, before and after the test occurs – leaving no gaps or room for human intervention from the moment field data is captured in the system, to specimen curing and identification, to validation and testing, to sign off and next steps.

In this two-way integration, CMT software preloads specimen data collected at the field into the testing machine, allowing the machine to validate the test based on the sample date, size, type, expected strength, and other test parameters. This ensures that the right specimen is tested on the right date, associated with the right project. After the automatic test, results appear exactly where you need them.

In this connected construction ecosystem, the above three challenges are no more – and your automatic machine is even more powerful.

Conclusion

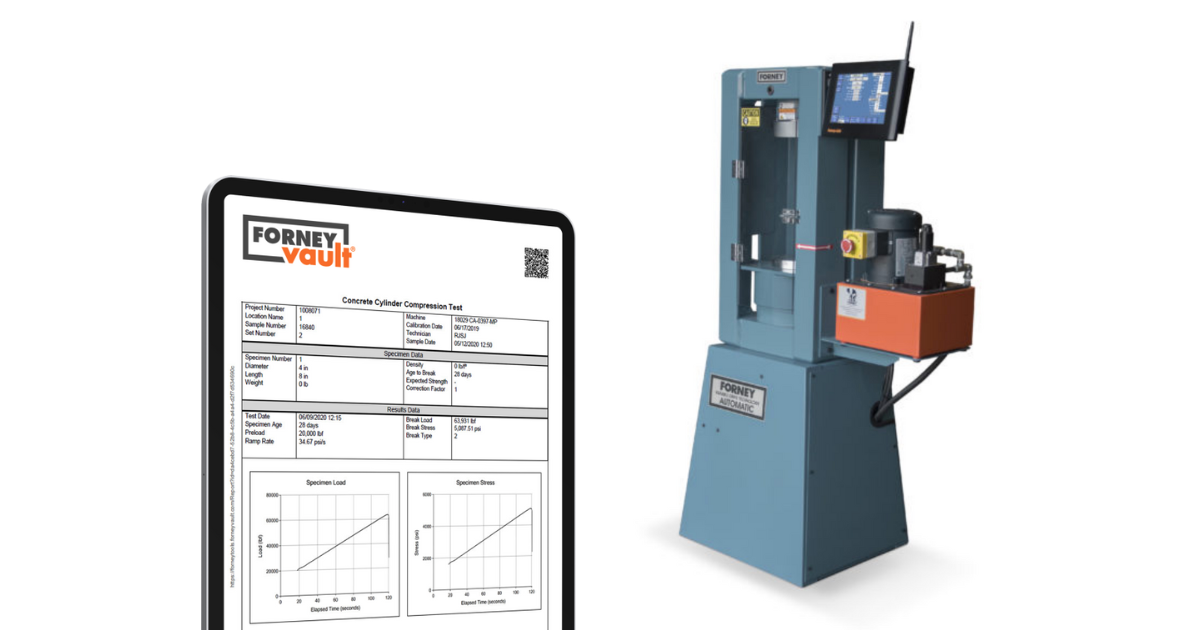

Manual machines are becoming obsolete. Now, the question for many CMT labs is this: How can I get even more benefits out of my automatic machine? Machine-integrated CMT software is the answer.

Forney offers powerful automatic testing machines and CMT software to fully connect your construction materials testing workflow. See how it all works by scheduling a demo.