Manufacturers have to meet exact specifications for their customers, which means QA/QC testing is a critical part of the manufacturing process. To ensure customers know they are receiving quality products, more and more manufacturers are turning to automation. Here’s why – and how to get there for your own organization.

Manufacturers producing anything from industrial rubber and composite railroad ties to steel and precast concrete – need to make sure the product they sell is not only safe and compliant but also exactly what the customer ordered.

This is where quality assurance/quality control comes in.

Testing as a part of the QA/QC process helps manufacturers improve performance, quality and consistency of the product. Legacy processes can accomplish these goals but with much less efficiency, which has become a must-have in the industry. This is only possible if the testing workflow is faster and accurate.

The problem is, most testing workflows are manual, which means they’re slow, inconsistent and susceptible to errors. Not to mention, manual testing machines are expensive to maintain and typically have a shorter life span.

This vulnerability in the testing process translates to vulnerability in product quality – at least in the eyes of your customers. Here’s how replacing manual with automatic testing machines can help.

3 Benefits of Automatic Testing for Manufacturers

#1. Eliminate Errors & Variability

Automatic testing machines remove the possibility of operator error in a few ways.

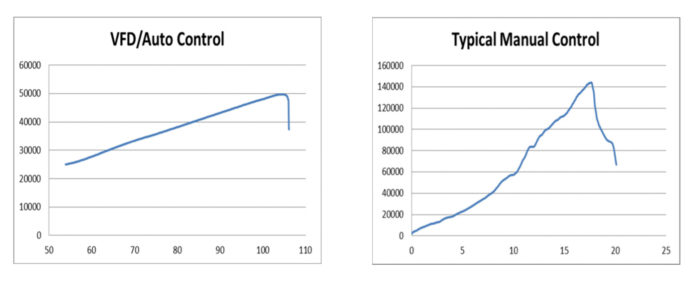

First, the testing machine automatically preloads the test specimen information before the test, which means the test is reliably set up from the beginning. Then, all the operator needs to do is click a button to run the test. Throughout the test, the machine automatically adjusts the rate setting, removing the variability that comes from manual rate adjustments. The difference is stark:

Ultimately, the automatic controls create consistent, repeatable tests that improve accuracy and meet regulatory and project specifications. After the test, results can be stored on the machine, printed or transferred to USB flash drive or cloud-based network, removing the possibility of losing or miswriting data.

Plus, busy machine operators can save time and let tests run on autopilot without impacting the accuracy and reliability of test results.

#2. Streamline Testing Controls

As mentioned, automatic testing streamlines the entire testing process from start to finish. The “one-touch” testing protocol allows for automatic preload, test and data recording before returning to the home position – ready for cleaning and subsequent testing. This allows technicians to complete other tasks while the testing is taking place.

Also, thanks to automatic preload and rate control, tests can be run at the higher end of test speed tolerance, so more tests can be completed in a shorter time span. This saves manufacturers time and money without worrying about a negative impact on test accuracy and reliability.

#3. Ensure Customer Peace of Mind

Of course, the previously mentioned benefits lead us back to a key stakeholder: the customer. When the QA/QC process is enhanced with automatic product testing, manufacturers benefit from more productive, accurate and transparent processes – and customers benefit from the peace of mind the process provides.

Automation gives manufacturers a unique competitive edge because they are more certain test results are reliable and accurate – and customers can fully trust the quality of the product.

How to Achieve Automated Product Testing

Automation offers a clear opportunity and path for manufacturers. But how do you get there?

For many, this starts with the machines you’re testing with. There are two ways you can automate testing:

- Invest in an automatic testing machine

- Upgrade your manual machine to automatic

Investing in an automatic testing machine is the quickest way to integrate automation into your existing system – but, while well worth the investment, it’s not cheap to buy an entirely new machine. Especially if your manual machine is not yet at the end of its life.

So, there’s another option: upgrade your manual machine to automatic. All you have to do is purchase retrofit equipment, remove power and hardware from your manual machine, and connect automatic controls, a new hydraulic hose and a limit switch. From there, you can plug in your machine, calibrate and run automatic tests.

This is what we define as semi-automated materials testing. But if you want to take your automation a step further, you can bring the entire testing process together with machine-integrated testing software.

Testing software drives even more accuracy and trustworthiness in the quality of your products because the solution automates how data moves through the testing process, better structuring and securing that data forever. The results are more accurate and traceable – doubling down on peace of mind for your customers.

Conclusion

Automation is the best way to enhance the process in which you verify the quality of your products. Free from operator error and variable results, automatic product testing machines are an investment that can bring your company to the next level.

Whether you’re ready for a complete overhaul of your product testing infrastructure or can only automate specific elements of your existing process, considering automation in some way shape or form will give you a competitive edge. When customers can fully trust that your products are as high-quality as you say they are, you will stand out in your market as an expert and leader.

Need help finding a new testing machine? Want to learn more about upgrading to an automatic? Tell us about your needs and we’ll be in touch.