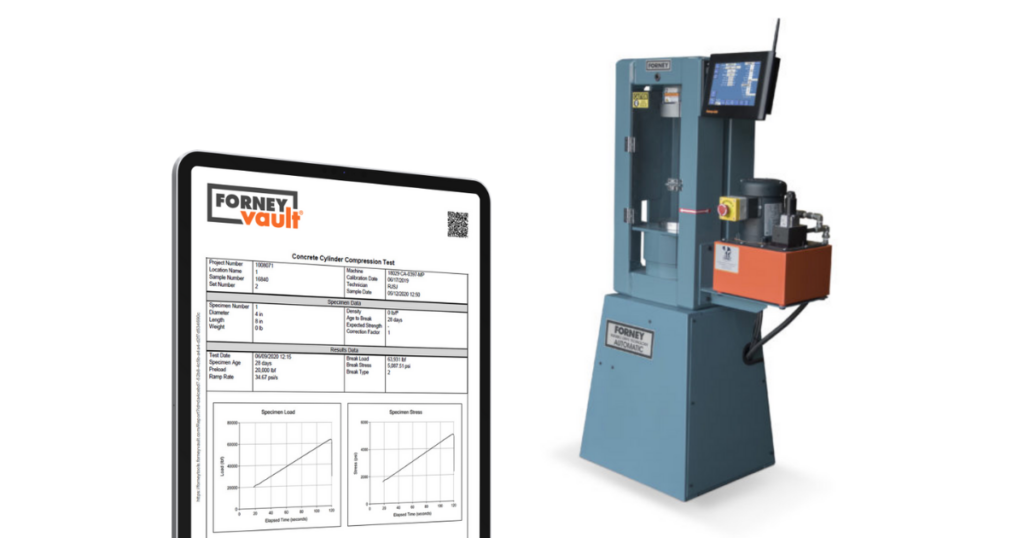

CONNECTED CONSTRUCTION MATERIALS TESTING MACHINES

A Connected CMT Machine offers all the benefits of Automatic plus a two-way integration with material testing software, resulting in 99.9%+ fewer manual errors, 66%+ increase in productivity, and 100% unalterable, unquestionable data.

NATIVE TWO-WAY INTEGRATION WITH CMT SOFTWARE

A Connected CMT Machine natively integrates with CMT software, ForneyVault, providing powerful benefits before and after the lab strength test occurs.

Before Strength Testing

ForneyVault creates unique identifiers tied to sample and field data for each specimen. At the Connected Machine, this enables:

- Positive specimen identification via barcode scan.

- Pre-test “Smart Checks” based on preloaded sample and specimen data to validate sample date, sample size and type, expected strength, and specimen geometry.

- Automatic calculations for preload settings based on expected strength.

After Strength Testing

ForneyVault enables intelligent workflows for detailed reporting and approvals. Powered by ForneyVault, the Connected Machine:

- Automatically transfers data to LIMS package, QC systems, or other software.

- Produces XY plot data for every test performed.

- Alerts to warn calibration expiration.

- Sends notifications about correction factors, individual low breaks, and excessive variance.

FORNEY CONNECTED MACHINES

Get the quality, precision and dependability you know and love in Forney testing machines, now with Connected controls. Connected Machines integrate with ForneyVault, CMT software that automates how you test and report on construction materials.

COMPRESSION

High-strength concrete testing

FLEXURAL

Versatile beam testing

TENSION/UNIVERSAL

Universal testing for a wide range of specimens

EXPLORE THE CONNECTED MACHINE INTERFACE

Empower your machine technicians to get more done faster with minimal human error by getting a Forney Connected CMT Machine. What does this look like at the machine? See how a ForneyVault-enabled machine interface works by taking a self-guided Product Tour.

GET A CONNECTED MACHINE

LEARN MORE ABOUT CONNECTED

CONSTRUCTION MATERIALS TESTING MACHINES

Get the Latest from Forney In your inbox

Enter your email below to subscribe for updated news on Forney’s construction materials testing solutions.