The test machine is at the heart of construction materials testing and the data that informs the entire project. That’s why machine manufacturers work to continuously improve these machines, bringing better levels of accuracy and efficiency to CMT labs. The latest improvement: Connected CMT Machines. Here’s what this means and how it compares to the legacy manual and automatic options.

The right construction materials testing machine for your lab largely depends on the materials and geometries you need to test, the type of tests you need to run, and the maximum strength of your specimens.

These parameters will inform which of these three machine types you should select:

- Compression: determines a material’s behavior under applied crushing loads.

- Flexural: produces tensile and compressive stress under bending force.

- Universal/tension: measures force, displacement, velocity and strain in tension or compression.

Once you have selected your machine type, though, there’s one more decision you have to make: the control system.

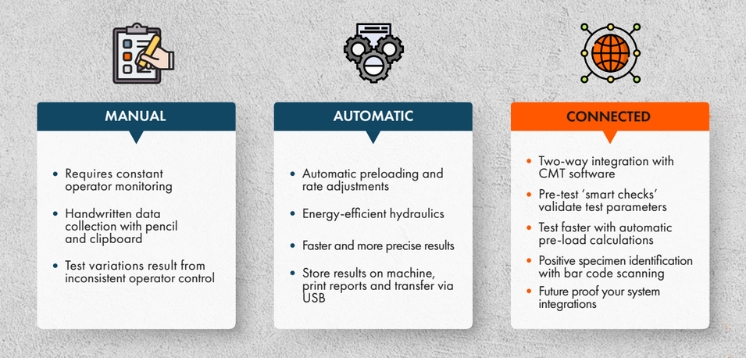

Typically, there are two options: manual control or automatic control. Today, though, there’s an option one step above automatic: connected. Here’s the difference.

Manual vs. Automatic vs. Connected CMT Machines

#1. Manual CMT Machines

Manual controls are exactly what they sound like.

Machine technicians have to manually operate the full advance, metering and hold controls throughout the entire test. This subjects the test to variance and error by nature of inconsistent, imprecise human control.

It’s also a slower test. While some operators may choose to let manual tests run by themselves to save time (causing more consistency challenges), they are supposed to be present at the machine the entire time to monitor the load rate and adjust the speed of the machine as needed. This takes technicians away from other value-added tasks and limits their capacity for a higher volume of tests.

Finally, manual machines have a shorter component life compared to their automatic and connected counterparts. The manual hydraulics lack a way to control energy and oil flow, so they are prone to overheating. In addition to a shorter component life, overheating causes poorer load rate control and inconsistent tests.

#2. Automatic CMT Machines

Automatic controls solve many of the above problems.

Machine technicians only have to start the test at the push of the button and clean the machine after the test completes. The machine handles the rest, including automatic preload, rate adjustments and data recording before returning to the home position.

Busy machine operators can let tests run on autopilot without impacting the accuracy and reliability of test results. This means they can run tests at the high end of the allowable range, reducing overall testing time and increasing the number of tests in a given shift.

Automatic machines have energy-efficient hydraulic systems, so they last longer than manual machines.

For years, automatic machines have been the better choice. But there’s still one more option.

#3. Connected CMT Machines

Connected controls include all of the features of an automatic testing machine while layering on additional benefits for the construction materials testing workflow.

The biggest difference: A connected machine natively integrates with CMT software. This isn’t just an integration from machine to software for data collection purposes. This is a two-way integration, before and after the test occurs.

Before the test, a connected machine will:

- Enable positive specimen identification via barcode scan.

- Provide pre-test “Smart Checks” based on preloaded sample and specimen data to validate sample date, sample size and type, and expected strength.

- Validate specimen geometry.

- Calculate preload settings based on expected strength.

After the test, a connected machine will:

- Provide a detailed XY plot data for every test performed.

- Transfer data automatically to LIMS packages, QC systems, or other software.

- Alert to warn calibration expiration.

- Notify correction factor use, individual low breaks, and excessive variance.

- Enable intelligent workflows for detailed reporting and approvals.

PRODUCT TOUR: See what connected controls look like at the machine

Automatic machines make the test itself foolproof. Connected CMT machines take this a step further by securing the entire workflow.

From the moment field data is captured in the CMT software, there are no gaps that require human intervention. With connected controls, your automatic machine is even more powerful – and the entire CMT workflow benefits.

INFOGRAPHIC: What does Connected Construction look like in the QA/QC workflow?

How to Get Connected Controls

Connected CMT machines are powered by a two-way integration with CMT software.

Modern construction is no stranger to software tools that enhance specific parts of the construction project. While you might have something called construction materials testing software or concrete testing software or similar, not all solutions enable the two-way integration that powers true connected construction.

ForneyVault is the only machine-integrated CMT software that helps technicians get more done faster with minimal human error. While ForneyVault is compatible with any machine from any manufacturer, the best results are with an automatic machine.

- If you already have an automatic machine, you can connect your controls by upgrading with a ForneyVault subscription.

- If you’re buying a new machine, you can save $1,500 by getting it with connected controls.

Conclusion

Strength testing is an essential part of the CMT workflow, which means the machine you deploy to test that strength is just as essential.

The industry has made great strides by moving from manual to automatic, but now you can do even better with connected controls. CMT labs with connected machines experience 99.9%+ fewer manual errors, 66%+ increase in productivity, and 100% unalterable, unquestionable data.

Learn more about connecting your CMT workflow here, and contact sales for a demo and quote here.