ASPHALT TESTING EQUIPMENT

Asphalt Binder Testing

Asphalt Analysis

Asphalt Sample Preparation and Collection

Asphalt Mix Design

About Asphalt Testing Equipment

+ What is asphalt?

Asphalt is a composite construction material that’s used for pavement. Asphalt is a mixture of aggregates and a binder (bitumen). Bitumen is a sticky, black, and highly viscous liquid or semi-solid form of petroleum.

To create asphalt, aggregates are heated and mixed with the bitumen. The mixture is then laid and compacted to form a durable, smooth surface. There are different types of asphalt mix designs for different applications. For example:

- Hot mix asphalt: used in areas with high traffic loads. Hot mix asphalt is the most common type of asphalt used for road construction.

- Porous asphalt: used in areas where stormwater management is crucial. Porous asphalt is designed with a high percentage of open space, allowing water to drain through the surface.

- Cold mix asphalt: used for temporary repairs or in situations where hot mix asphalt isn’t readily available. Cold mix asphalt be used in colder weather and is more flexible and suitable for minor repairs.

In 1984, the U.S. Transportation Research Board urged the development of more durable paving materials for highways, inspiring the Superpave system (SUperior PERforming Asphalt PAVEments). The Superpave system is a hot-mix asphalt design method that helps engineers and contractors design and construct asphalt pavements that perform better and last longer under extreme temperatures and traffic loads. Also referred to as performance-based mix design, Superpave incorporates three main components: (1) asphalt binder specification, (2) aggregate gradation specification, and (3) mix design procedure.

+ What is asphalt testing?

Asphalt testing is the process of evaluating asphalt materials for quality, durability and performance. This includes:

- Asphalt binder testing: Asphalt binder testing is essential to ensure the quality and performance of the binder in asphalt mixtures and, consequently, in the overall durability and functionality of paved surfaces. The testing assesses various characteristics of the asphalt binder, including rheological properties, viscosity, chemical composition, adhesion and cohesion, performance grading, elastic recovery, and compatibility.

- Asphalt mix testing: Asphalt mix testing involves evaluating various characteristics of the asphalt mixture to ensure it meets specified performance criteria.

- Marshall stability: Measures the load-carrying capacity and flow resistance of an asphalt mixture under specified conditions.

- Bulk specific gravity: Measures the ratio of the mass of a compacted asphalt mixture to the mass of an equal volume of water.

- Air void content: Determines the percentage of air voids in a compacted asphalt mixture.

- Extraction testing: Determines the asphalt binder content in a sample by dissolving the binder in a solvent.

- Rolling thin film oven testing: measures the effect of heat and air on a moving film of semi-solid asphaltic materials.

+ What is asphalt testing equipment?

Asphalt testing equipment includes a range of specialized instruments and machinery designed for assessing the physical, mechanical, and rheological properties of asphalt materials. These tools are utilized to perform tests such as Marshall stability, binder extraction, and mixture analysis to ensure the quality, durability, and performance of asphalt pavements. Forney stocks a wide variety of asphalt testing supplies that satisfy ASTM, AASHTO and ISO standards, including but not limited to:

- Asphalt sample preparation and collection supplies: equipment to prepare asphalt samples for testing, including core extractors, asphalt concrete and cement mixers, dispensing hot pots, mixer heater adapter kits, and sample dividers.

- Asphalt content furnace: ignites asphalt mix samples to extract asphalt binder from the mixture and determine the percentage of asphalt binder in the total mix. The asphalt mix sample is heated in the furnace, causing the binder to burn off while leaving behind aggregates. The remaining material is weighed, and the loss of weight is used to calculate the asphalt binder content.

- Centrifuge extractor: used for quantitative determinations of bitumen content in hot-mixed asphalt paving mixtures and paving samples for specification, acceptance, service evaluation, control and research.

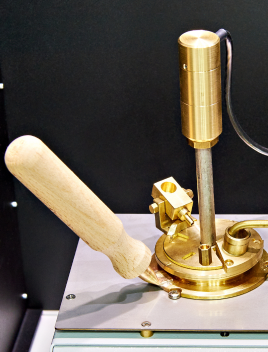

- Penetrometer: provides a direct reading for precision penetration measurements of bituminous materials.

- Viscometer: determines the viscosity of petroleum liquids at temperatures from ambient to 464°F (240°C).

- Vacuum extractor: used for the quantitative determination of bitumen in hot-mix asphalt paving mixtures using the vacuum method.

- Marshall stability tester: used to evaluate the stability and flow of asphalt mixtures by subjecting compacted specimens to vertical loads, simulating traffic-induced stresses, and measuring the maximum load that the specimen can withstand before deformation.

- Bending beam rheometer: assesses the low-temperature performance of asphalt binders by subjecting a thin film of the binder to repeated bending under controlled conditions.

- Rolling thin film oven: analyzes the effect of heat and air on a sample of semi-solid asphalt.

Other Asphalt Testing Equipment Resources

Asphalt testing is an important part of road construction, ensuring the quality and durability of the infrastructure used every day. Here are some other helpful resources related to asphalt testing and equipment: