Automatic CMT machines already provide significant advantages in terms of accuracy, consistency, and repeatability. However, the potential benefits extend even further when these machines are integrated with specialized CMT software and equipped with barcode scanners. This combination enhances testing efficiency, data management, and traceability, unlocking a new level of precision in strength testing. Here’s how it works.

More construction material testers than not use automatic CMT machines every day. The standard of modern strength testing, automatic machines make processes and products better.

But testing organizations are still looking for more. Human nature means specimens can still be misidentified and test results can still be mishandled.

READ MORE: 3 Reasons Why You Need More Than Just an Automatic Materials Testing Machine

To meet this need, Forney introduced a new type of machine: Connected. Using a Forney Connected Machine, a technician can load and test a specimen twice as fast — and with complete assurance that they are testing the right specimen at the right time.

What Is a Connected CMT Machine?

A Connected CMT Machine is a type of material testing machine that integrates with ForneyVault CMT software. This integration is powerful because it’s two-way, both before and after the test occurs (instead of only after).

Before the test, a Connected Machine runs pre-test “Smart Checks” based on specimen and sample data from ForneyVault. After the test, a Connected Machine automatically transfers data wherever it needs to go and provides helpful alerts, notifications and original XY plot data.

READ MORE: 3 Benefits of CMT Software for Material Machine Users

Here’s more about why these “Smart Checks” matter – and how barcode scanning helps make it happen.

How Barcode Scanning Works

The biggest difference with a Connected CMT Machine is how CMT software makes the machine “smart” by preloading the machine with sample and specimen data.

This context gives the machine the ability to run “Smart Checks” and carry out important pre-test steps, including:

- Automatic specimen identification

- Test parameters validation

- Preload calculation

Barcode scanning is the best way to trigger this process. Before we take a deep dive at the machine, here’s a brief overview of how it works:

- ForneyVault creates a unique identifier for every specimen, tying it to sample information.

- Once specimens are received and stripped, technicians can apply a barcode label to each one.

- When it’s time to test, technicians scan this barcode label at the machine, using the unique identifier to automatically display pertinent data associated with the specimen.

Keep reading for the steps in more detail, including a video of what it looks like at the machine.

How Barcode Scanning with a Connected CMT Machine Works

#1. Generate a Unique ID

When a sample is created at the job site, wet concrete data is captured – ideally, through a field application. At this time, specimens for lab strength testing are also cast. With a ForneyVault subscription, this is where a unique identifier is generated, tied to the sample the specimen came from and the project as a whole.

Read More: QA/QC Field Testing Tips for Wet Concrete Properties

Then, this ID can be turned into a barcode, which is printed on a label and affixed to the specimen. Each barcode is securely attached using adhesive labels designed to withstand the demands of the curing environment, ensuring their integrity and readability throughout the testing process.

These unique barcode labels establish a clear digital footprint for each specimen and lay the groundwork for the Connected CMT Machine functionality.

#2. Scan Barcode

Once the specimen is ready to test, the next step is scanning the barcode at the testing machine. When a technician scans the barcode label using a machine-mounted scanner, the associated information is displayed on the machine.

ForneyVault Bar Code Label Scanning Quick Tour from ForneyVault on Vimeo.

Upon scan, the machine initiates “Smart Checks” to identify the specimen and validate the testing process: break age, specimen size and type, ramp rate, and preload value.

#3. Run Test

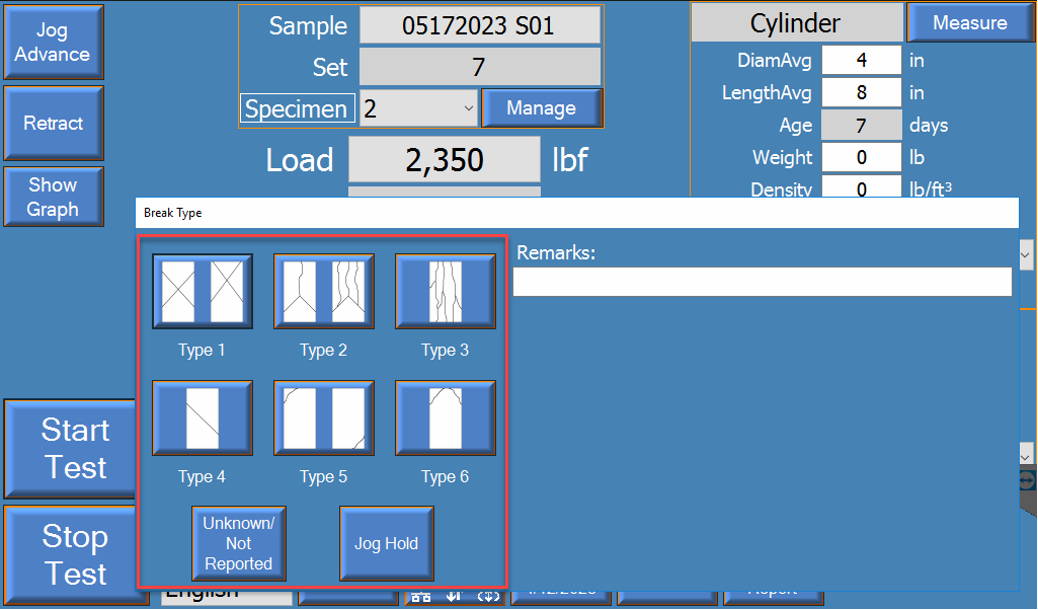

After ensuring the test is ready, push Start Test on the machine interface.

The machine conducts the test according to the predefined parameters and configured settings. Connected CMT Machines still offer all the benefits of automatic, including:

- Automatic preloading and rate adjustments.

- Energy-efficient hydraulic systems that eliminate excess oil flow.

- Automatic testing and results transfer.

This combination of connectivity and automatic testing allows lab technicians to focus on value-added tasks rather than manual data entry or manual machine control.

#4. Review Results

After the test, the technician selects the appropriate ASTM C39 break type and can add any necessary remarks.

Data is then instantly transferred to ForneyVault, ensuring unalterable, compliant test results.

Although the testing procedure has been completed, Connected CMT Machines continue to work in the background, providing:

- A detailed XY plot data for every test performed.

- Alerts and notifications about calibration expiration, correction factors, individual low breaks, and excessive variance.

- Intelligent workflows for detailed reporting and approvals.

Conclusion

Specimen identification and pre-test processes are important to get right. Barcode labels make this process as accurate as it can be, giving technicians an easy way to scan an ID, preload machines with the associated information, and test with confidence.

Connected CMT Machines – equipped with barcode scanners – result in 99.9%+ fewer manual errors, 66%+ increase in productivity, and 100% unalterable, unquestionable data. Get a quote today.