CONSTRUCTION MATERIALS TESTING LAB EQUIPMENT

Lab Essentials

Scales & Balances

Lab Heating Elements

Thermometers

Timers & Stopwatches

Vacuum Pumps and Equipment

CMT Software Supplies

About Construction Materials Testing Lab Equipment

+ What is a construction materials testing lab?

A construction materials testing lab assesses the physical and mechanical properties of materials used in construction projects, ensuring they meet specified standards and regulations. Its primary purpose is to evaluate the quality, strength, and durability of construction materials such as concrete, asphalt, soil, aggregates, and various other substances.

In the lab, trained technicians conduct a series of tests to measure characteristics like compressive strength, flexure strength, force, pressure, strain and more. The results help engineers, architects and construction professionals make informed decisions about the suitability of materials for specific applications, assuring that the constructed infrastructure meets safety and performance requirements.

+ What is construction materials testing lab equipment?

Construction materials testing lab equipment is a set of specialized instruments and apparatus used to assess construction materials' physical and mechanical properties. Types of construction materials testing lab equipment include:

- Lab essentials: fundamental tools and instruments that are indispensable for conducting accurate and comprehensive analyses of construction materials. These essential items include everything from brushes and rubber mallets to personal safety gear and pH meters.

- Brushes: tools used to perform various lab tasks, from sample preparation to equipment cleaning. Forney offers a variety of brush types, including a fine sieve brush, wire brush, coarse sieve brush and stiff wire brush.

- Rubber mallets: tools used to consolidate construction materials and release entrapped air in concrete molds, air meters and unit-weight buckets. Forney mallets are made from hard molded rubber and attached to a straight handle.

- pH meter checkers: devices that assess the pH levels of substances such as concrete mixes or various chemical solutions used in testing procedures. Forney’s pH meter measures pH from 0.00 to 14.00 with an accuracy of ±0.2 pH units.

- Tamping rods: tools used for eliminating air voids in concrete in preparation for slump testing, preparing concrete cylinders and performing air entrainment tests. Forney tamping rods are made out of steel.

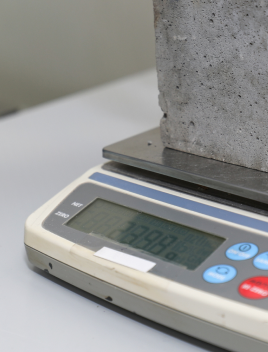

- Scales: devices used for measuring the mass or weight of construction materials with a focus on general weight determination rather than high precision.

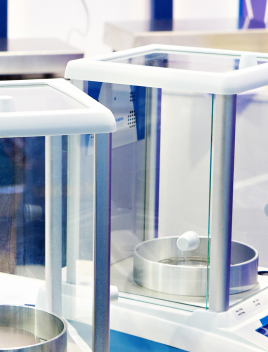

- Balances: precision measuring instruments used to determine the mass or weight of construction materials. These devices are crucial for conducting various tests and analyses in construction laboratories, ensuring that the quantities of materials used in experiments or quality control processes are measured precisely.

- Furnaces: high-temperature heating devices designed to subject construction materials to extreme heat for specific testing and processing purposes. These specialized furnaces are used to simulate conditions such as extreme temperatures, fire resistance or thermal endurance that construction materials might encounter during their lifecycle.

- Ovens: specialized heating devices that apply controlled and elevated temperatures to samples for various testing purposes. They are designed to create consistent and uniform heat environments, allowing construction materials to undergo processes like drying, curing or heat-related testing.

- Hot plates and stoves: heating devices that apply controlled temperatures to samples during construction materials testing laboratory experiments.

- ASTM Thermometers: specialized temperature-measuring devices that adhere to standards established by the American Society for Testing and Materials (ASTM). They help maintain consistency and comparability in temperature measurements, contributing to the reliability and standardization of processes in material testing. Forney ASTM thermometers meet ASTM E1.

- Infrared Thermometers: non-contact temperature measurement devices that utilize infrared technology to quickly and efficiently assess the temperature of construction material surfaces. This provides essential data for quality control and ensures compliance with temperature-related specifications during various construction processes.

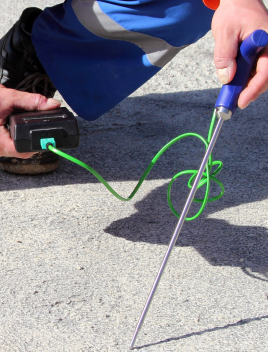

- Concrete Thermometers: specialized temperature-measuring devices designed for monitoring and assessing the temperature of freshly mixed concrete during its placement, curing and early stages of hardening.

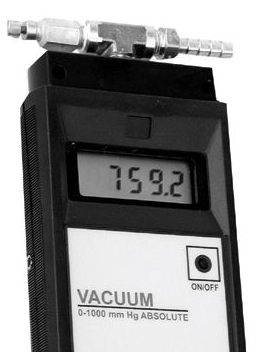

- Vacuum gauges: instruments used to measure the vacuum or negative pressure level within sealed testing chambers or equipment.

- Vacuum pumps: mechanical devices designed to create and maintain a vacuum within testing chambers or apparatus. These pumps remove air or other gases from the enclosed space, creating a negative-pressure environment.

+ What is construction materials testing software?

Construction materials testing software is a platform that connects field data to lab testing machines and other third-party software, uniting data flow across the entire construction ecosystem.

- In the field: Technicians can capture sample data, claim and locate specimens on-site, and sync that field reporting data with the lab.

- In the CMT lab: The material testing machine automatically loads with field data. With this information, it “knows” what it’s testing, preventing specimens from being tested on the wrong date.

- After the test: Results automatically flow to reporting software. Then, project stakeholders can get real-time text or email notifications of any lab updates, problems or next steps, making the entire workflow faster and more actionable.

+ What lab equipment do you need for CMT software?

This type of CMT software requires the right hardware in order to connect field data to the testing machine in the lab.

- Barcode scanner: a device that reads and captures information from barcodes affixed to construction material specimens. After the barcode scans a specimen, information associated with that specimen automatically preloads into the testing machine.

- Machine interface: a user-friendly, interactive touch panel displaying pertinent material testing data and specimen details. Forney’s human machine interface (HMI) works with most manufacturer’s testing machines.

- Testing Machine: a specialized piece of lab equipment that performs various tests, including compression, tension, bending and shear tests. This provides crucial data for quality control and ensures the materials meet specified standards and performance criteria.

Other Construction Materials Testing Lab Equipment Resources

Construction materials testing lab equipment plays a crucial role in ensuring the quality, safety and reliability of construction materials. Browse our useful resources related to CMT lab equipment and software:

- Construction Materials Testing Protocols [Full Listing]

- Glossary of Construction Materials Testing Terms

- Construction Materials Testing: 3 Essential Solutions for the Modern Testing Lab

- Concrete Testing Equipment Essential: 6 Categories

- CMT Software: Build or Buy? 3 Factors to Consider

- 3 Benefits of CMT Software for Material Machine Users